Nothing is more important than structural integrity when designing a large structure, like a bridge, dam, or skyscraper.

The last thing you want is a weakness that puts human lives at risk if there is a collapse.

Structural design is the discipline of calculating the different load requirements of various structures and designing a structure that will easily withstand worst-case scenarios — like a 100-year storm.

In this article, we’ll further explain what structural design is about, including the different types and applications, along with a better way of managing your civil engineering projects.

What is structural design?

Structural design is a sub-discipline of civil engineering, which deals with the design of a robust and usable structure. Depending on the goals of the building project, they may also work with architects to create a unique, visually appealing design — think the Eiffel Tower.

Structural engineers use “structural analysis” and other calculations to ensure that the building will be structurally sound before you move the first shovel of dirt.

Essentially, it’s the art of turning an architect’s ideas into reality. You factor in the actual loads in the design.

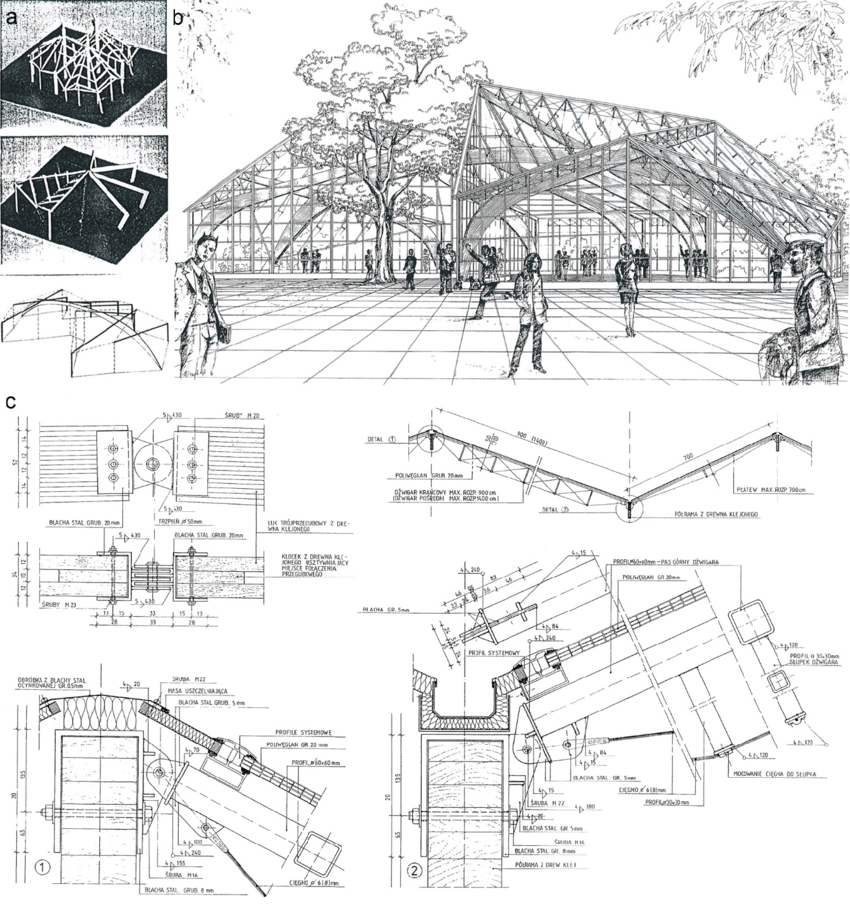

Structural sketches focus on a building’s framework, usability, and key structural details and features that enable the architect’s design.

In this example from a Warsaw University of Technology student, you can see how complex considerations can be to achieve aesthetic shapes.

That’s what sets a structural drawing apart from an architectural sketch. It adds these extra details.

What are the types of structural design?

There are various types of structural design depending on use case, materials, and type of structure.

2 common types are:

- Rigid frame: a building supported by a framework with welded joints. The structural members — in this case, beams and columns — can take a certain amount of bending moment, shear, and axial loads.

- Concrete shell: a building without internal columns and buttresses, but rather a concrete shell usually in an oval shape.

The loads and forces you have to calculate change with the type of building you design. The structural design engineer has to consider a lot of different factors.

Some of these include:

- Shear: this is the stress generated by different parts of the structure moving in different directions. The most extreme examples occur during an earthquake.

- Tensile: essentially, this is a pulling force on any part, like a wire or beam, that can elongate or break it.

- Compressive: this force pushes down on the structure — for example, its regular weight and the weight of all the interior plus everyone inside.

Some structural engineers also specialize in design counteracting one specific risk, like storms or earthquakes.

Some of the most common include:

- Wind design: in locations with extremely strong winds, there might be a focus on wind-resistant designs.

- Earthquake or seismic design: this is the act of designing structures that can withstand earthquakes. For example, focusing on creating buildings with an even center of mass to reduce torsion and introducing unique elements to improve damping — the absorption of vibrations.

For example, Taipei 101, the 10th tallest building in the world, has a “tuned mass damper.” That’s a 700-ton hanging ball that absorbs vibrations. It’s part of the system that helped the building withstand a heavy earthquake in 2008 when many other buildings didn’t.

Other structural engineers specialize in different types of materials, like mass timber rather than concrete and steel.

Each material has unique properties that make it easier or harder to create certain shapes and types of buildings.

Buildings with important uses, like hospitals, have special building codes and requirements, so some structural designers specialize only in them.

All of the most famous buildings in the world use complex structural design concepts to avoid collapsing. For example, the Sydney Opera House takes advantage of hidden hinges and split-arch beams to tie it together into its seamless appearance.

What are the requirements of structural design?

The main structural design requirements are stability, strength, and serviceability, but it doesn’t stop there.

Here’s a quick list of things you must consider when designing a building or structure.

- Stability to prevent sliding, overturning, or buckling of the structure, or parts of it, under the action of environmental and live loads.

- Strength to safely resist the stresses induced by loads in the various structural members. The building shouldn’t crumble under its own weight.

- Serviceability to ensure satisfactory performance under service load conditions. This implies providing adequate stiffness and reinforcements to contain deflections, crack widths, and vibrations within acceptable limits.

- Aesthetics depending on the project, looks, and a visible internal structure, may also be a priority.

- Economy means that being able to satisfy requirements 1 to 3 within the budget is critical. Knowledge of various materials, their price range, and their applications is essential here.

How to do structural calculations

As a structural engineer, your first job is to figure out the potential loads and stresses the finished structure will go through.

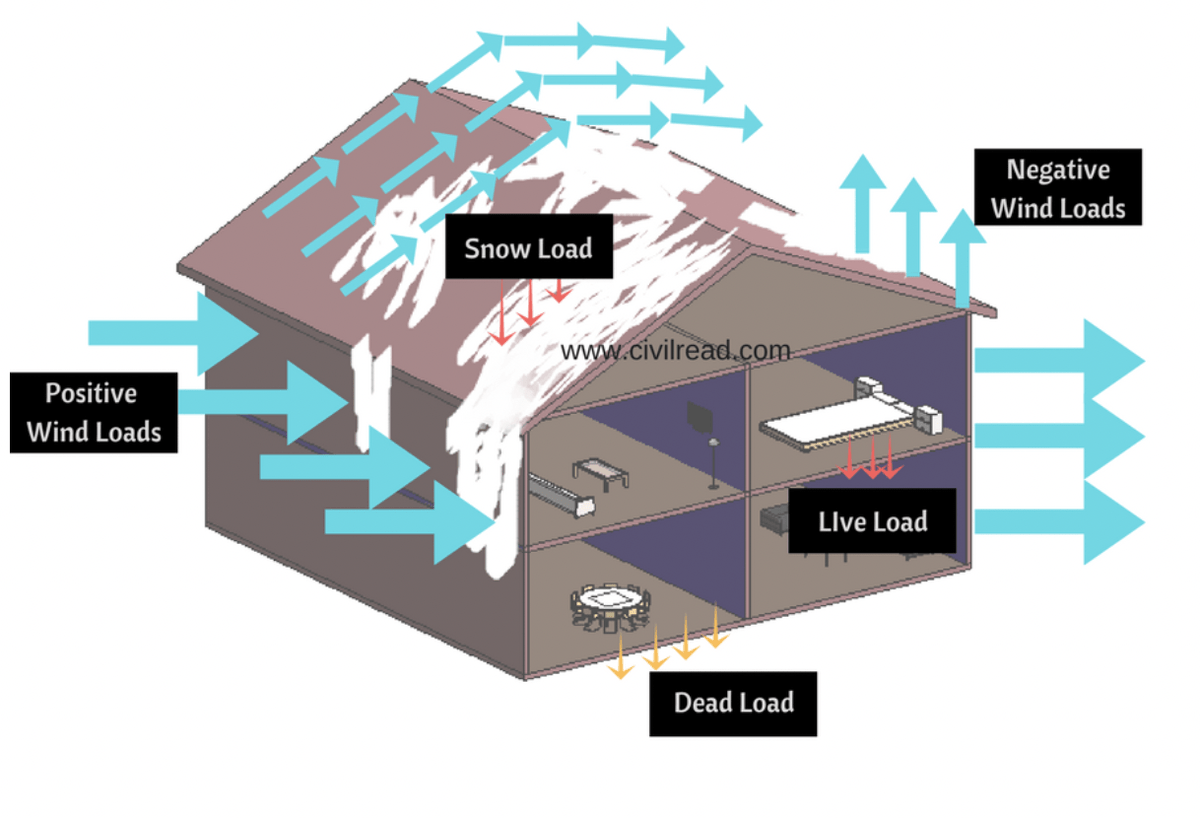

3 main types of loads impact your calculations: live, dead, and environmental loads.

- Live loads come from the occupants, furniture, vehicles, and equipment.

- Dead loads are caused by the weight of the building itself.

- Environmental loads are inflicted by the forces of nature, such as wind, earthquakes, and snow. The expected lateral load and required strength vary greatly based on location.

Your local building code will highlight the appropriate load — particularly the third category — but you still have to do the calculations.

When you’re calculating the dead loads, everything, including the load-bearing elements themselves, must be included.

Even for a simple concrete building, you must include:

- The self-weight of columns times the number of floors

- The self-weight of beams per running meter

- The load of walls per running meter

- The total load of slab

These numbers vary greatly based on the type of materials used. For example, steel weighs over 8,000 kg per cubic meter. That’s easily a ton or 1 kN of force per floor, even for a standard steel column.

Crunching all these numbers is the first stage of every large construction project.

Essentially, once you have figured out all the loads, you calculate the number of load-bearing walls, beams, what materials are appropriate for the project, and more.

Of course, if you add any extra load-bearing structural members, you need to calculate that added self-weight as well.

You then have to reconcile all this information with the architect’s design and the client’s budget.

It’s not an easy job. Usually, it’s done in close collaboration with an architect and a surveyor.

Thankfully, you can use specialized construction software to handle most of the calculations and modeling. With software like Clearcalcs, you can apply standards-based calculations to your project based on your location, building type, and more.

But the software doesn’t handle everything. You still need to make the design based on this data. That’s the hard part. You’re the structural design engineer, after all.

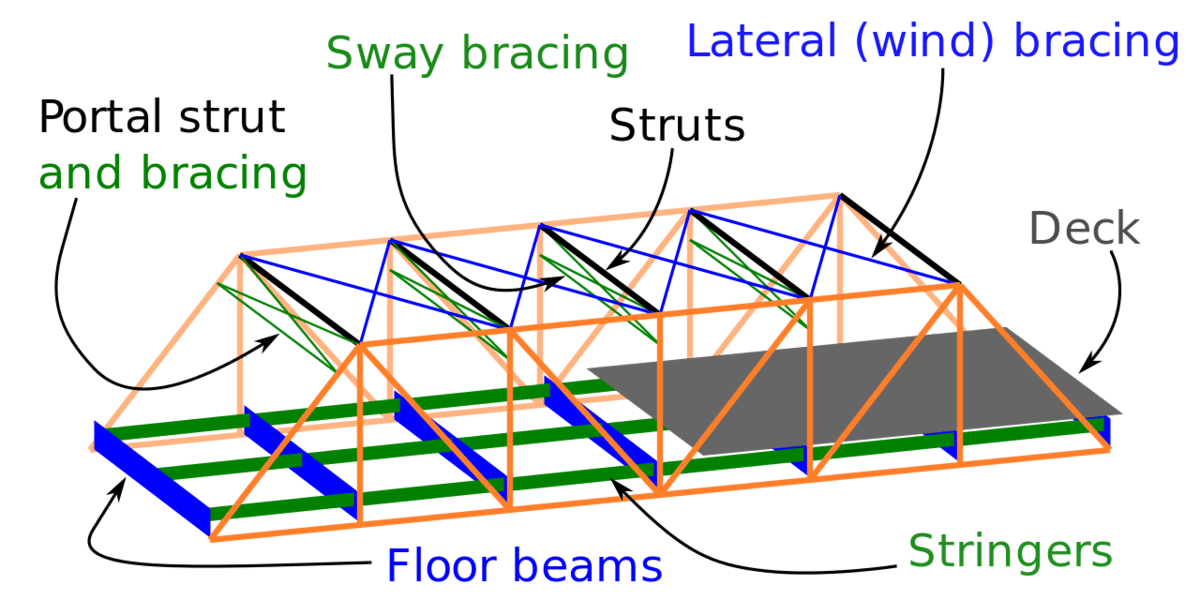

The results of these calculations are most visible in designs where you see the skeleton. Think bridges, where you can see struts and braces for wind and other loads with your naked eye.

Even for regular office buildings, experienced engineers have made similar considerations, but the frame and other elements are hidden from sight.

Does your company handle structural design projects? Are you struggling to keep up with them all at the same time? There may be a software solution for you.

How to manage structural design projects better with monday.com

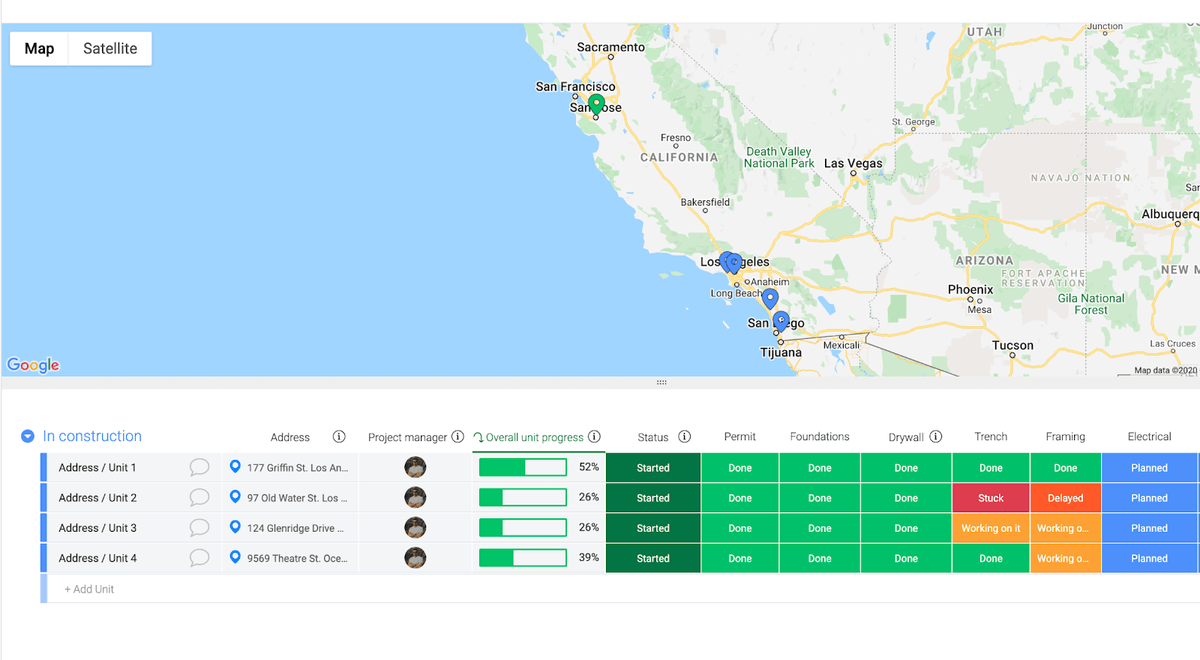

If you’ve got a large backlog of structural design projects, you need a good way to organize them.

On average, major construction projects finish a year behind schedule and 30% over budget.

The last thing you want is to become part of that statistic. Good luck getting repeat business from those clients.

With a proper construction project management system in place, you can stay on top of all moving parts and reduce the risk of both delays and unforeseen costs.

monday.com lets you create a custom platform tailored to your teams and workflow.

Here’s how:

Use our construction planning template to keep track of your projects.

We offer several templates tailor-made for construction and engineering companies. They make it easy to keep track of different areas, surveying and building schedules, permit dates, resources, and more.

A robust construction planner is crucial for dealing with delays. With the color-coded grid, you can easily identify any projects at risk of going over schedule and focus your attention there.

By consistently finishing projects on time, you can build a loyal client base.

Include design files, CAD drawings, calculation results, and more in the board.

Structural design involves a lot of data and digital files.

You no longer need to delegate these crucial files to an email thread or an employee’s hard drive. You can add them directly to the relevant project on the board.

That makes it easier for everyone to find the data they need. If they want to recalculate something, they can find the original data with a click.

Poor file organization can slow down the progress of a project and put customer relationships at risk. Don’t fall victim to that. Change the way you handle your files.

Map out objectives and milestones visually with Gantt charts.

monday.com isn’t only useful for creating a high-level construction timeline. In the early stages of a building’s design, there are a lot of smaller milestones. For example, when you finish the perspective sketch of the project.

Instead of having these as major stages in a multiple-project overview, you can have a separate board for design processes.

With monday.com, you can easily visualize single boards in detail. Create a Gantt chart or a timeline view by adding expected timelines to your deliverables.

Manage specific workflows with boards and automations.

You can’t just rely on everyone to collaborate smoothly. You must create a system that makes it easy to work together.

With monday.com, you can easily create custom workflow boards for different aspects of a project. Add or remove columns and fields until you’re left with the most crucial.

You can also use our automation builder to streamline your workflows further. Set up automated notifications when projects are overdue or enter a certain stage.

That way, you can guarantee the right person is on the case at all times.

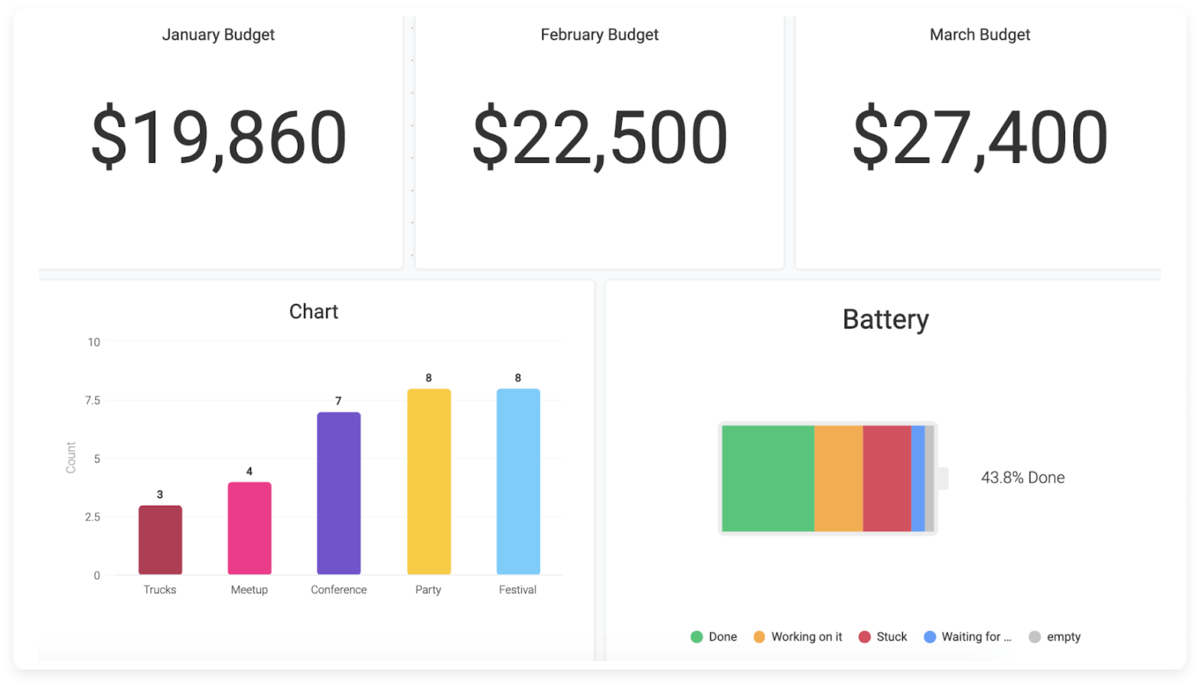

Track progress against expectations with real-time dashboards and reports.

Milestones are useless unless you follow up on them. We offer real-time dashboards to test your expectations.

Don’t rely on feeling or guesswork. Use widgets to create a custom dashboard that shows what you want to see.

See exactly how your projects perform with custom data points you highlight yourself.

Structural design is easier with a well-designed process

Structural design has been around since the pyramids of Egypt, the Aqueducts of Rome, and probably even before.

But the fact that the discipline is old doesn’t make managing a structural design project today any easier.

With a lot of changing factors and people from multiple teams and companies involved, it can be hard to stay on the same page.

Use our customizable construction management template to get a new level of control over your structural engineering projects.