Efficient warehouse operations drive both profitability and customer satisfaction. Teams need software that streamlines logistics into a predictable, scalable process. The right system connects warehouse data with the rest of the business, giving every department the same clear view.

This article covers the essential capabilities of warehouse management software, what to look for when choosing a solution, and the top 10 platforms available in 2025.

Try monday work managementWhat is a warehouse management system?

A warehouse management system (WMS) manages every stage of warehouse operations, from receiving inventory to shipping orders. It provides a central place to track stock, manage orders, and automate workflows. Real-time visibility ensures teams know what’s in stock, where it is, and where it’s headed next.

WMS platforms replace manual tasks and spreadsheets with digital records and automated processes. Tracking every item across receiving, picking, and packing reduces errors and prevents costly delays.

A connected system extends this visibility across departments. Linking warehouse data with sales, procurement, and customer service gives the entire business a shared, accurate view of operations.

What your warehouse management software should do for you

Warehouse management software should simplify daily operations and give teams the tools to perform at their best. Core capabilities include accurate inventory tracking, efficient fulfillment, and clear reporting that supports smarter decisions.

Know what you have as soon as it arrives

Accurate inventory starts with receiving. Features like barcode scanning and real-time stock updates eliminate manual entry errors. Teams can rely on precise counts and know exactly where to find every item.

Pick, pack, and ship with speed

Automated pick paths and packing verification reduce mistakes and shorten order processing time. Teams spend less time searching and more time fulfilling orders.

See the big picture

Dashboards and reports provide real-time insights into key metrics such as fulfillment speed and inventory turnover. Trends and bottlenecks are easier to identify, making it possible to resolve issues before they impact performance.

How to choose the right warehouse management software solution

Selecting warehouse software should focus on fit and flexibility. A strong system adapts to the way your team works and scales as your business grows. Key factors to consider include integration, automation, and total cost.

Integration and scalability

The system should connect seamlessly with tools like enterprise resource planning and e-commerce platforms. Eliminating silos ensures all teams share the same data. Look for a platform that can scale during seasonal peaks or expansion without requiring a major overhaul.

Automation and AI potential

Automation reduces repetitive work and improves accuracy. AI features can categorize inventory, process shipping documents, or trigger alerts for low stock and delays. A platform like monday work management includes built-in AI tools that streamline these tasks and give teams more time for higher-value work.

Cost and support

Evaluate the full cost of ownership, including licensing, training, and ongoing maintenance. Pricing models vary — per-user and flat fee structures are common. Strong support is essential, especially during onboarding, to ensure your team can get the most value from the system.

10 best warehouse management systems

Choosing warehouse software is a critical decision when balancing inventory, speed, and costs. The right system streamlines operations with automation and real-time visibility, helping teams reduce errors and improve fulfillment.

This list highlights each system’s strengths, best-fit users, and key features so you can select the option that aligns with your business goals.

1. monday work management

monday work management connects warehouse operations to the wider business ecosystem. It provides customizable workflows and cross-department visibility, making it suitable for organizations that want flexible warehouse management at scale.

Use case: Teams can manage warehouse operations alongside broader business workflows and adapt the system to fit their unique processes.

Key features:

- Real-time inventory tracking with automated low-stock alerts and customizable product catalogs

- Mobile barcode scanning through marketplace integrations for on-the-go inventory management

- Dynamic dashboards that visualize key warehouse metrics without relying on spreadsheets

Pricing:

- Free: $0 forever, up to 2 seats with 3 boards and 200+ templates

- Basic: $9 per seat/month (minimum 3 seats) with unlimited items and 5GB storage

- Standard: $12 per seat/month with Timeline, Calendar views, and 250 automation actions monthly

- Pro: $19 per seat/month with private boards, time tracking, and 25,000 automation actions monthly

- Enterprise: Custom pricing with 250,000 automation actions monthly and advanced security

- Annual billing saves 18% compared to monthly billing

- Nonprofit organizations may qualify for additional discounts

Why it stands out:

- Connects warehouse operations seamlessly with sales, marketing, and project management workflows

- No-code customization allows non-technical teams to build sophisticated warehouse management systems

- Scales from small businesses to enterprises without forcing you into rigid, one-size-fits-all solutions

monday work management’s AI capabilities streamline warehouse operations through intelligent automation and data processing. The “Extract info from files” AI block automatically processes shipping documents and invoices, eliminating manual data entry. The “Categorize” AI feature intelligently sorts inventory items and organizes warehouse data, helping teams maintain accurate records without constant oversight.

The platform offers 200+ pre-built automation recipes that eliminate repetitive warehouse tasks without requiring coding knowledge. Teams can automatically send notifications for low inventory levels, process orders based on stock availability, and update inventory counts across multiple locations. Enterprise-scale automation handles up to 250,000 actions monthly, ensuring your warehouse operations run smoothly even as your business grows.

monday work management connects with over 72 external tools, including e-commerce platforms, shipping carriers, and ERP systems for unified supply chain management. The platform integrates seamlessly with popular tools like Salesforce, Google Drive, and Zapier, creating a connected ecosystem where warehouse data flows automatically between systems. API access enables custom integrations for specialized warehouse equipment and legacy systems.

The platform addresses core warehouse software challenges through customizable inventory tracking that adapts to any product type or storage method. Map view functionality provides visual oversight of third-party logistics and delivery locations, while cycle counting features simplify inventory audits using formulas and mobile access. File management software stores and organizes warehouse documents in the cloud, ensuring critical information like purchase orders and invoices are always accessible to your team.

Try monday work management2. Softeon WMS

Designed to optimize complex distribution networks, Softeon provides advanced warehouse management system software with flexible configuration and powerful analytics. The platform specializes in “micro-tuning” workflows to match unique business requirements, making it ideal for companies managing sophisticated supply chain operations. With 14 consecutive years as a Gartner “Visionary,” Softeon has earned recognition for its ability to handle everything from basic warehousing to highly automated Level 5 facilities.

Use case: Companies with complex distribution networks use Softeon to customize workflows, integrate automation, and manage advanced supply chain operations.

Key features:

- Micro-tuning capabilities that allow businesses to customize workflows without extensive coding requirements

- Integrated Warehouse Execution System (WES) for real-time orchestration of automated warehouse operations

- Comprehensive labor and yard management tools with performance tracking and optimization features

Pricing: Pricing information is not publicly available and requires contacting Softeon directly for a custom quote.

Considerations:

- Implementation complexity can be significant due to the high degree of customization options available

- The extensive feature set may be overwhelming for smaller operations with simpler warehousing needs

3. Infor WMS

With its industry-specific configurations and 3D visualization capabilities, Infor WMS provides enterprise-grade warehouse management that transforms complex distribution operations. The platform specializes in deep ERP integration, making it ideal for large-scale manufacturers and distributors managing multi-site operations.

Use case: Large manufacturers and distributors use Infor WMS to manage multi-site operations with industry-specific functionality and deep ERP integration.

Key features:

- Interactive 3D warehouse visualization for real-time workflow optimization and bottleneck identification

- Embedded labor management with productivity tracking and workforce forecasting capabilities

- Comprehensive 3PL billing and multi-client warehouse management with customer-specific workflows

Pricing:

- Pricing information not publicly available — contact Infor for custom enterprise quotes

Considerations:

- Steep learning curve due to extensive functionality and complex interface design

- Significant customization often required to meet specific industry requirements, particularly in regulated sectors

4. Oracle Warehouse Management Cloud

Oracle’s cloud-native platform transforms complex distribution operations into streamlined, automated workflows. It specializes in seamless integration with Oracle’s broader business suite, making it ideal for large organizations managing high-volume, multi-location warehouse operations.

Use case: Enterprises running high-volume, multi-location warehouses use Oracle WMS Cloud to unify inventory management, automation, and omnichannel fulfillment.

Key features:

- Real-time inventory tracking across all locations with lot, serial number, and cycle counting capabilities

- Advanced automation integration with material handling equipment, conveyors, and automated storage systems

- Omnichannel fulfillment support enabling “buy anywhere, fulfill anywhere, return anywhere” scenarios

Pricing: Oracle does not publish specific pricing for Warehouse Management Cloud. Contact Oracle Sales directly or use their Cost Estimator tool for customized quotes based on your organization’s requirements.

Considerations:

- High implementation costs and complexity may be prohibitive for smaller businesses

- Some users report system stability issues during high-growth periods and slower customer support response times

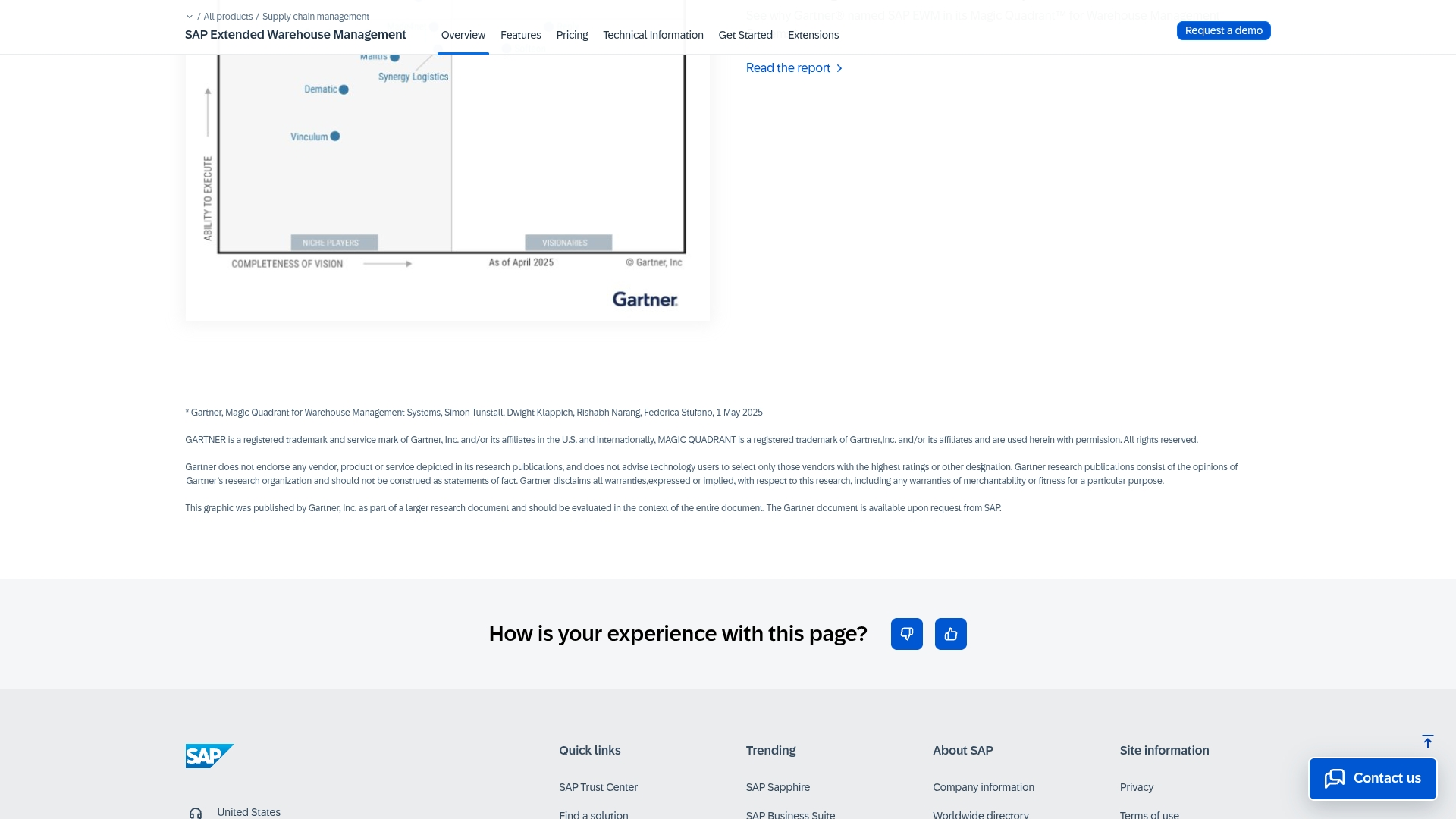

5. SAP EWM

Integrating tightly with SAP enterprise systems, SAP Extended Warehouse Management (EWM) offers advanced warehouse automation and process automation for organizations already invested in the SAP ecosystem. It’s best for complex, high-volume warehouse operations, standing out with its direct control of automated equipment and seamless integration across the entire supply chain.

Use case: Organizations already invested in SAP use Extended Warehouse Management to control automation, manage complex inventory, and integrate supply chain processes.

Key features:

- Advanced warehouse automation with direct control of robotics and material flow systems

- Real-time, bin-level inventory tracking with comprehensive batch and serial number management

- Integrated labor management and resource optimization tools for maximizing workforce efficiency

Pricing:

- Contact SAP directly for pricing information

- Pricing varies based on deployment model (embedded in S/4HANA vs. standalone)

- Enterprise-level investment required for licensing and implementation

Considerations:

- Complex implementation requiring specialized SAP consultants and significant time investment

- High total cost of ownership that may be prohibitive for smaller organizations

6. Manhattan Active WMS

Built on a cloud-native architecture, Manhattan Active WMS unifies distribution, labor, and automation within a single, versionless platform. The system specializes in quarterly updates without disruptive upgrades, making it ideal for high-volume, multi-channel operations that need continuous innovation.

Use case: Enterprises with multi-channel operations use Manhattan Active WMS to unify warehouse, labor, and execution systems within a cloud-native platform.

Key features:

- Cloud-native microservices architecture with automatic scaling and quarterly updates without downtime

- Unified platform combining warehouse management, labor management, and embedded warehouse execution system (WES)

- AI-driven order streaming that processes orders individually or in small batches based on priority and urgency

Pricing: Pricing information is not publicly available. Contact Manhattan Associates directly for custom quotes based on your specific warehouse management requirements and operational scale.

Considerations:

- Steep learning curve for new users, which can extend initial adoption timelines

- High implementation costs and ongoing support expenses may be prohibitive for smaller operations

7. Fishbowl

For small business management software needs, Fishbowl offers comprehensive warehouse management system software that integrates seamlessly with QuickBooks to streamline inventory operations. The platform is the top choice for QuickBooks users seeking robust inventory tracking without the complexity of enterprise-level solutions.

Use case: Small and mid-sized businesses that rely on QuickBooks use Fishbowl to automate inventory management and maintain real-time stock visibility across locations.

Key features:

- Real-time inventory tracking with barcode scanning capabilities across multiple warehouse locations

- Deep QuickBooks integration that synchronizes financial and inventory data automatically

- Multi-location management with automated reordering and transfer capabilities between warehouses

Pricing:

- Pricing information is not publicly available and requires contacting Fishbowl directly through their website

Considerations:

- Users report the interface feels outdated compared to modern warehouse management solutions

- The software has a steep learning curve and can be complex for teams new to warehouse management systems

8. Körber Supply Chain Software

Transforming complex logistics into streamlined, automated workflows is the core strength of Körber Supply Chain Software. The platform provides comprehensive solutions specializing in end-to-end supply chain visibility and omnichannel fulfillment capabilities, making it ideal for businesses managing intricate distribution networks and high-volume operations.

Use case: Businesses with complex distribution networks use Körber to integrate warehouse functions with robotics, predictive analytics, and multi-client 3PL support.

Key features:

- Comprehensive warehouse functionality including receiving, slotting, picking, packing, and advanced shipping management with real-time inventory visibility

- Advanced technology integration supporting IoT sensors, robotics, AI, and machine learning for predictive analytics and process optimization

- Multi-client 3PL support with flexible onboarding, configuration capabilities, and specialized industry solutions for automotive, petrochemical, and e-fulfillment sectors

Pricing: Contact Körber directly for pricing information and consultation on their warehouse management solutions.

Considerations:

- Implementation complexity can be significant for comprehensive WMS deployments, requiring detailed migration planning from legacy systems

- Some users indicate that cost relative to value could be improved, with technology updates needed in certain areas

9. Centric WMS

Specializing in mechanization and robotization control, Centric WMS offers comprehensive warehouse management solutions that turn complex logistics into streamlined, automated workflows. The platform is ideal for retail, wholesale, and third-party logistics companies managing high-volume, multi-channel operations.

Use case: Retailers, wholesalers, and third-party logistics providers use Centric WMS to manage high-volume operations with advanced mechanization and automation.

Key features:

- Real-time 3D warehouse visualization with KPI dashboards for enhanced operational visibility

- Fully integrated voice recognition system that eliminates middleware requirements and enables real-time task processing

- Advanced mechanization control that originated as material handling equipment (MHE) control system, providing superior automation integration

Pricing: No pricing information available — contact Centric directly for custom quotes based on your warehouse complexity and requirements.

Considerations:

- Higher implementation complexity due to advanced mechanization features may require longer deployment timelines

- Limited pricing transparency requires direct consultation, which could slow initial evaluation processes

10. Blue Yonder Warehouse Management

Leveraging AI-powered solutions, Blue Yonder transforms complex supply chain operations into predictive, autonomous systems. The platform’s strength lies in its machine learning-driven demand forecasting and optimization, making it ideal for large enterprises that need advanced enterprise workflow management software while managing sophisticated, high-volume warehouse networks.

Use case: Large enterprises use Blue Yonder to apply AI and machine learning across warehouse networks for predictive analytics, task management, and robotics integration.

Key features:

- AI-driven task management that dynamically prioritizes warehouse activities to maximize overall productivity

- Robotics hub for unified management of multiple automation vendors and warehouse robotics solutions

- Advanced yard management with computer vision and machine learning to optimize throughput and minimize cargo loss

Pricing:

- Custom quote required based on specific operational requirements and deployment scope

Considerations:

- High implementation complexity due to the comprehensive nature of the system and extensive customization options

- Significant upfront investment makes it more suitable for large enterprises with complex operations rather than smaller businesses

Adopting new technologies like AI and digital workforces

AI and automation enhance warehouse operations when they are integrated quickly and effectively. These technologies improve accuracy, reduce manual effort, and give teams more time for higher-value work.

- Automate routine tasks with AI: AI tools handle repetitive tasks such as processing shipping documents and categorizing inventory. Features like automatic data extraction and smart organization ensure records stay accurate without manual input.

- Empower your team with a digital workforce: A digital workforce manages recurring warehouse processes and adapts to ongoing needs. These AI-powered tools take on operational tasks at scale, allowing teams to focus on problem-solving, planning, and growth.

Unify your warehouse and your strategy

Warehouse software should align directly with business objectives. A unified system connects warehouse operations with company-wide goals, creating visibility that supports better decisions and faster execution.

monday work management gives teams one place to track inventory, manage shipments, and monitor performance alongside strategic initiatives. Warehouse data becomes part of the broader business plan, supported by project management tools that keep every task connected.

See how a connected warehouse can drive growth across your business. Start building a more efficient and aligned workflow today.

Get startedFAQs

What software is used in a warehouse?

Warehouses use warehouse management systems (WMS) to manage daily operations like inventory management, order fulfillment, and shipping. Solutions range from enterprise systems like SAP to flexible platforms like monday work management that connect warehouse data to other business functions.

What is the best warehouse management software?

The best system depends on the size of the business, the complexity of operations, and integration needs. Small and mid-size businesses often prioritize flexibility, while larger enterprises look for advanced automation and multi-site management.

What is SAP warehouse software?

SAP Extended Warehouse Management (EWM) is designed for large-scale operations. It offers detailed inventory tracking, process automation, and direct integration with other SAP products.

How does AI support warehouse management?

AI supports warehouse operations by automating repetitive processes such as data entry, demand forecasting, and route optimization. This improves speed and accuracy while reducing manual effort.

Can digital workers handle daily warehouse operations?

Yes. Automations and AI-powered tools can process documents, update records, and generate reports, allowing teams to focus on planning, oversight, and strategy.