Are your projects constantly battling delays? Do tasks seem to stretch on forever, leaving your team feeling overworked and stakeholders antsy? You’re likely grappling with extended lead times. Understanding and optimizing lead time in your work management processes isn’t just about speed; it’s about efficiency, predictability, and delivering value faster.

This guide will show you exactly how to define, measure, and slash lead times using smart work management strategies and the power of a platform like monday.com. Let’s get your projects back on track.

Ready to see how monday.com can help you slash lead times?

What does lead time mean?

lead time refers to the total time elapsed from the moment a new task, project, or work item is requested or initiated until it’s delivered or completed.

While traditionally prominent in supply chain and manufacturing, understanding lead time is critical for any team managing projects, from software development sprints to marketing campaigns.

You need to carefully calculate and account for lead times to avoid project delays, missed deadlines, and inefficient resource utilization.

Defining lead time for projects, tasks, and processes

For projects, lead time is the entire duration from project approval to final delivery. For individual tasks, it’s the time from when a task is made available or assigned to when it’s marked as done. In terms of processes (like client onboarding or content creation), lead time measures the end-to-end duration of that specific workflow.

We’ll explore different types of lead time relevant to work management more in a later section.

Why it’s different from cycle time (and why both matter)

It’s crucial to distinguish lead time from cycle time. Lead time is what the customer or stakeholder experiences – the total wait time.

Cycle time, on the other hand, typically measures the duration from when work actively begins on a task to when it’s completed.

For example, a task might have a lead time of 5 days (from request to delivery) but a cycle time of only 2 days (the actual work duration, excluding wait times).

Understanding both helps identify different types of delays and inefficiencies in your workflow optimization efforts.

Why tracking and reducing lead time is crucial for your team’s success

Effectively tracking and reducing lead time isn’t just a nice-to-have, it’s fundamental to your team’s performance and overall project success.

Here’s why focusing on lead time can transform your team’s output:

Boosting productivity and meeting deadlines

Shorter lead times mean your team can accomplish more in less time. By identifying and eliminating delays, you improve flow, which directly translates to hitting deadlines more consistently and increasing overall team productivity.

Improving stakeholder satisfaction

Whether your stakeholders are internal clients, external customers, or company leadership, faster and more predictable delivery times lead to higher satisfaction. Meeting or exceeding expectations on turnaround time builds trust and strengthens relationships.

Gaining a competitive advantage

In fast-paced environments, the ability to deliver quality work quickly can be a significant differentiator. Efficient lead time management allows your team to be more agile and responsive to changing demands.

Optimizing resource allocation

Understanding your lead times helps you better predict workload and allocate resources effectively. By minimizing idle time and bottlenecks, you ensure your team members are working on value-adding activities.

This also leads to cost reduction by minimizing wasted effort and the costs associated with delays.

Cost reduction

In line with the previous point, this reason also has significant effects on a business’s bottom-line.

Downtime and wastage all cost money, whether it’s in storage costs or the cost of unsellable, spoiled goods.

Reducing lead times means increasing profitability, and you can only perform lead time reduction after having figured out current lead times.

Customer satisfaction

Ignoring the competitive element of offering better lead times, customers and clients will typically end up more satisfied with your services if they are fulfilled quicker.

The added value of shorter lead times will encourage customer loyalty and positively impact your future revenues.

Key types of lead time to monitor

To effectively manage and improve lead times, it’s helpful to break them down into more specific types relevant to your team’s workflows:

Customer lead time (from request to delivery)

This is the total time a customer or stakeholder waits from the moment they make a request until the final product or service is delivered. It’s often the most critical lead time from an external perspective.

Task/item lead time (from start to completion)

This measures the time it takes for an individual task or work item to go through your entire process, from the point it’s officially started or pulled into “in progress” until it’s considered complete. This is closely related to cycle time but can include queue times if “start” is defined as when it enters the backlog.

Project lead time (overall project duration)

This is the total duration of a project, from initiation (e.g., project charter approval) to final closure and delivery of all project outcomes.

Development lead time

For teams using monday.com for software development, this could refer to the time from when a feature is committed to (e.g., pulled into a sprint) until it’s deployed to production. This is a key metric in Agile and DevOps practices.

Supply chain management

In supply chain management, lead time refers to the time it takes for a supplier company to have goods ready for delivery. While distinct, principles from supply chain lead time (like managing supplier dependencies) can apply to project management when dealing with external vendors or inter-departmental handoffs.

For example, an apparel company may have a 7-day lead time for custom t-shirts. Typically, this measurement does not include shipping time.

Manufacturing lead time

For a manufacturing company, the definition accounts for shipping as well as manufacturing time in turning around goods for a client.

This is because manufacturers need to know exactly when parts requested are ready to be constructed with other parts, using the most efficient manufacturing practices.

Order lead time

Order lead time applies to traditional B2C (business-to-consumer) contexts, and it refers to the time it takes for a good to be received by a customer starting from the receipt of the customer’s order.

Project management

In project management, lead time mostly refers to the time it takes — or time that is allowed — to finish something. Lead time in this context could refer to the completion of a single task or an expansive team project.

How to accurately calculate lead time in your workflows

Calculating lead time in your work management workflows requires clearly defined start and end points.

Identifying start and end points for different processes

Before you can calculate, you must agree on what constitutes the ‘start’ and ‘end’ of a process or task. For example:

- Task Lead Time: Starts when a task status changes to “In Progress” (or is assigned) and ends when status is “Done.”

- Project Lead Time: Starts on the official project kick-off date and ends on the date of final deliverable acceptance.

- Content Creation Lead Time: Starts when a brief is approved and ends when content is published.

Simple formulas and examples for project management

The basic formula for lead time is:

Lead Time = End Date/Time – Start Date/Time

For example, if a marketing task (e.g., “Design social media graphic”) is assigned on Monday at 9 AM and completed on Wednesday at 5 PM, the lead time is 2 days and 8 hours (or 2.33 business days if you only count working hours).

Consider Little’s Law for a higher-level view, especially for continuous flows: Average Lead Time = Average Work in Progress (WIP) / Average Throughput (completion rate). This can help understand system-level lead times.

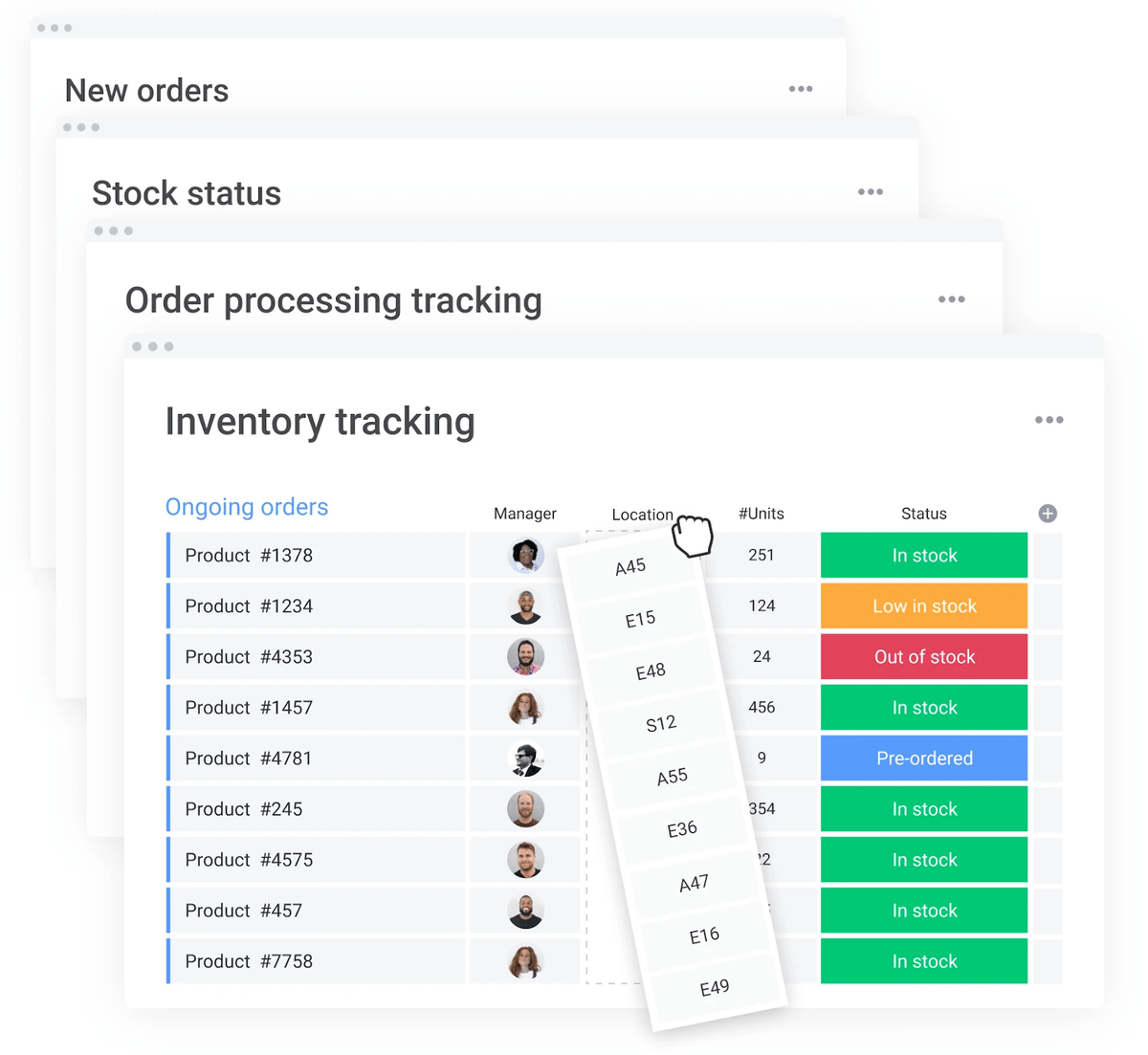

Using monday.com to automatically track lead times (mention relevant columns/views)

Manually tracking can be tedious. monday.com makes it easy! You can:

- Use Date columns to mark start and end dates.

- Employ the Formula column to automatically calculate the difference between these dates. For instance:

DAYS({End Date}, {Start Date})orWORKDAYS({End Date}, {Start Date}). - Utilize Time Tracking columns to log actual effort, which can be compared against lead time.

- Visualize lead times directly on Gantt charts or Kanban boards (by tracking time in status).

- Create Dashboards with widgets to display average lead times for different projects or task types. Learn more about monday.com dashboards.

Common bottlenecks that inflate lead times in project management (And how to avoid them)

Identifying bottlenecks is key to reducing lead times. Here are common culprits in work management:

Unclear requirements and scope creep

When task or project requirements are vague or constantly changing, it leads to rework and delays. Spot this by observing frequent clarification requests or tasks getting stuck in review cycles.

Waiting for dependencies or approvals

Tasks often stall waiting for input from other teams, information from stakeholders, or necessary approvals. Look for tasks piling up in “Waiting” or “Pending Approval” statuses on your Kanban board.

Too much Work in Progress (WIP)

When team members juggle too many tasks simultaneously, context switching reduces focus and slows everything down. High WIP is a classic sign that lead times will suffer. Limiting WIP is a core tenet of Kanban.

Inefficient handoffs between team members

Poorly defined handoff processes can lead to information loss, delays, and errors. This often occurs when there’s no clear system for transferring work and context between individuals or teams.

Now that you can identify common bottlenecks, let’s explore how monday.com empowers you to eliminate them and significantly reduce your lead times.

Actionable strategies to reduce lead time with monday.com

Reducing lead time isn’t just about working faster, it’s about working smarter. monday.com provides a powerful suite of tools to help you streamline workflows, enhance collaboration, and ultimately slash your lead times.

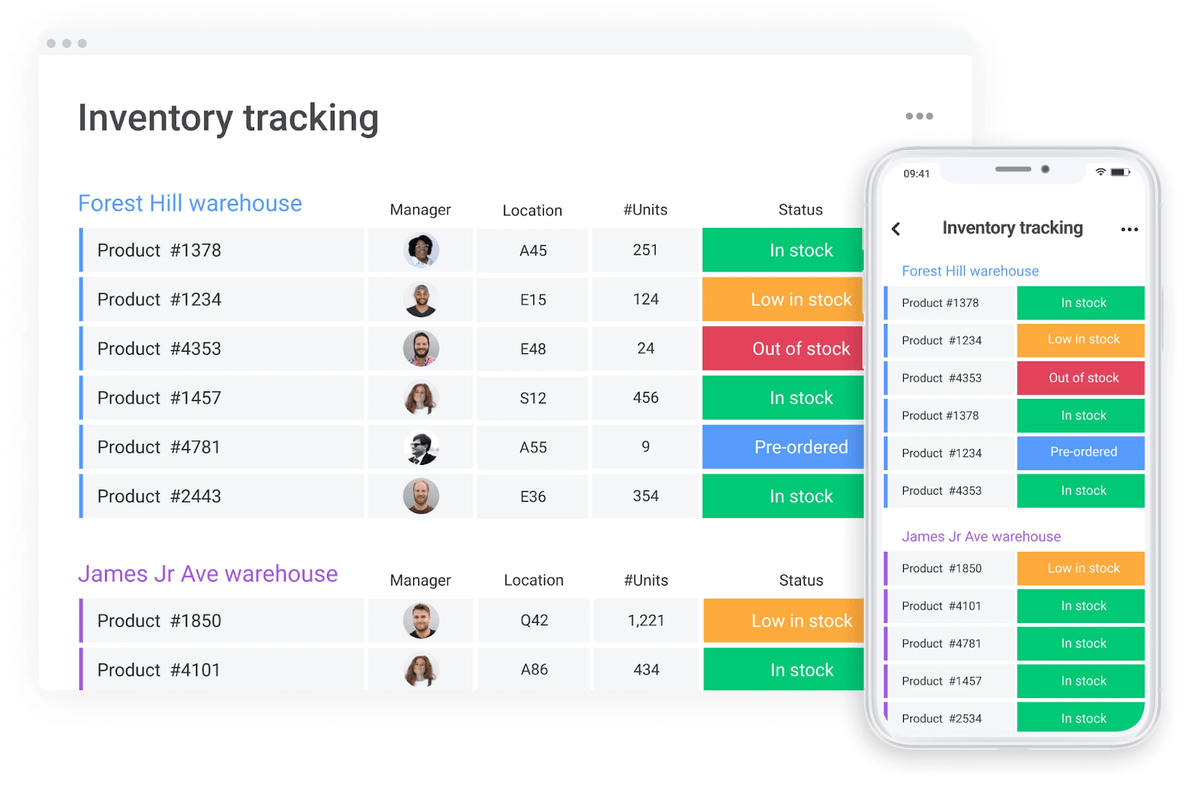

Visualize your workflow with Kanban and Gantt views

Understanding where work gets stuck is the first step.

Use monday.com’s Kanban views to map out your process stages and see tasks flow through. This helps you spot bottlenecks where items accumulate. Implement WIP limits on Kanban columns to prevent overload.

Gantt charts are excellent for visualizing project timelines, dependencies, and critical paths, helping you proactively manage potential delays. Explore monday.com’s Gantt chart features.

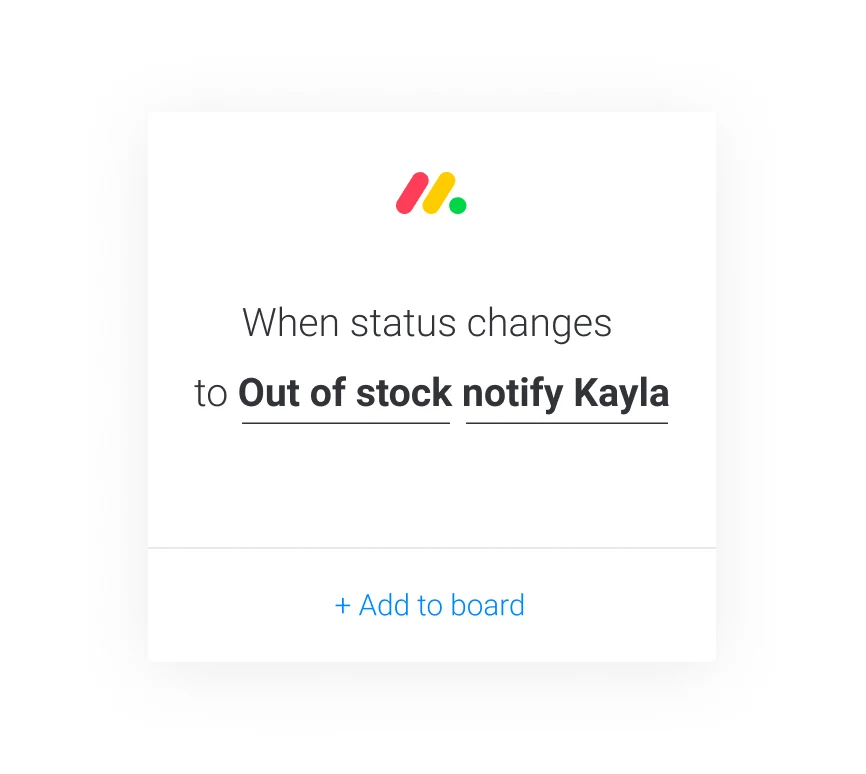

Streamline processes with custom automations

Manual handoffs, status updates, and notifications are major time sinks.

monday.com Automations can take over these routine tasks. For example:

- Automatically notify the next person in line when a task status changes.

- Move items between groups or boards based on triggers (e.g., when a task is marked “Ready for Review”).

- Send reminders for upcoming deadlines or overdue tasks.

- Create recurring tasks automatically.

This reduces idle time and ensures work keeps moving. Discover monday.com Automations.

Enhance collaboration and communication

Miscommunication and siloed information are significant contributors to delays. monday.com centralizes all project-related communication and files in one place. Use item updates for discussions, attach relevant files directly to tasks, and @mention team members to ensure everyone stays informed. This reduces the need for endless email chains and meetings.

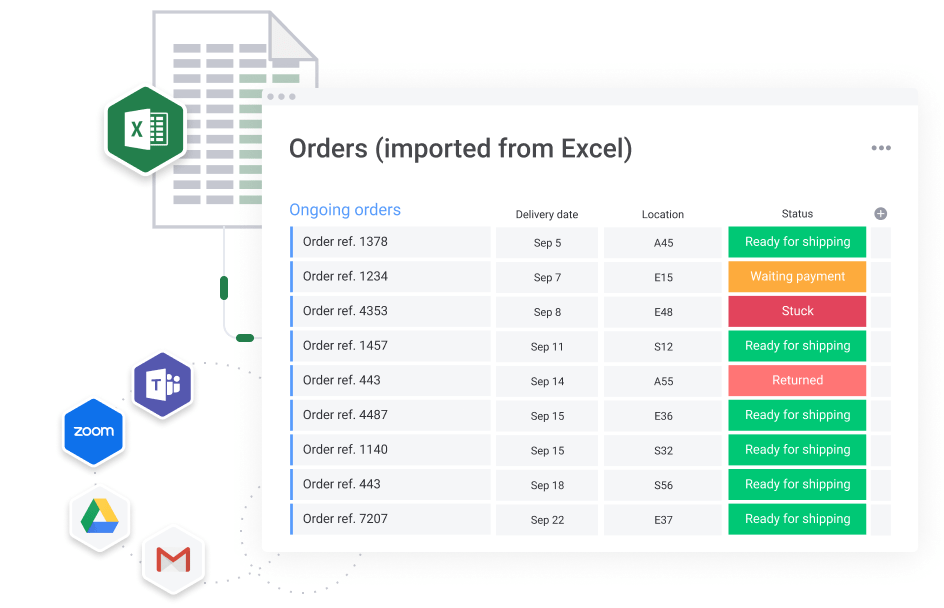

Integrate your existing tools for seamless data flow

If your team uses multiple tools, ensure data flows seamlessly between them.

monday.com offers numerous integrations with popular apps like Slack, Gmail, Outlook, Jira, Salesforce, and more. This means you can sync data, trigger actions across platforms, and keep monday.com as your central source of truth for work management, reducing manual data entry and potential errors. Explore monday.com Integrations.

Utilize templates for faster project setup

Don’t reinvent the wheel for every new project or process. monday.com offers a wide range of pre-built templates for various use cases (project management, marketing, software development, etc.). These templates often come with pre-configured columns, views, and automations designed to optimize workflows from the start, saving setup time and ensuring consistency. You can also create and save your own custom templates.

Monitor progress with real-time dashboards and reports

You can’t improve what you don’t measure. Use monday.com Dashboards to create custom reports that track key lead time metrics, identify trends, and monitor team performance in real-time. Widgets like the Chart widget, Numbers widget, and Time Tracking widget can provide valuable insights into where your lead times are longest and where improvements are having an impact. This data-driven approach allows for continuous optimization.

Automate your lead time tracking and notifications. Explore monday.com Automations.

Examples of improving lead time in different project management scenarios

Agile software development sprint

A development team uses a monday.com board to manage their two-week sprints. They notice their average lead time for user stories is creeping up. By visualizing their workflow on a Kanban view, they identify a bottleneck in the “Code Review” stage.

They implement a WIP limit on “Code Review” and set up automations to notify reviewers immediately when a story is ready. They also use dashboards to track lead time per story type, helping them refine estimates. This reduces their average story lead time from 8 days to 5 days within two sprints.

Marketing campaign execution

A marketing team plans and executes campaigns using a shared monday.com board. They struggle with delays due to slow approvals for creative assets. They redesign their workflow to include clear approval stages with assigned owners and automated reminders for pending approvals.

They also use a marketing calendar template integrated with their task board for better visibility. This cuts their average creative approval lead time by 40%.

Client onboarding process

A customer success team uses monday.com to manage new client onboarding. Their lead time from contract signed to fully onboarded was inconsistent. They standardized their onboarding process using a monday.com template, with automated task creation for each step (kick-off call, training, setup).

They integrated their CRM so new client deals automatically create an onboarding item on their board. This ensures no client falls through the cracks and reduces average onboarding lead time by 3 days, improving customer satisfaction.

Take control of your lead times with monday.com

Mastering your lead times is essential for staying competitive and delivering exceptional results. The demand for quicker turnarounds and greater efficiency is constant, whether you’re managing internal projects or client-facing deliverables.

While every team’s needs are unique, the principles of clear processes, smart automation, and proactive monitoring are universal. monday.com provides the flexible Work OS you need to design and optimize lead time management workflows tailored to your specific requirements.

Stop letting delays dictate your timelines. By leveraging features like customizable boards, insightful dashboards, powerful automations, and seamless integrations, you can identify bottlenecks, streamline handoffs, and empower your team to work more efficiently.

Transform your team’s efficiency and take full control of your project timelines. Try monday.com Work Management today and start reducing your lead times for better, faster outcomes.

FAQs

What's the difference between lead time and cycle time?

Lead time is the total time from when a request is made until it's delivered to the customer/stakeholder. Cycle time is typically the time from when active work begins on a task until it's completed. Lead time includes all waiting or queue times, while cycle time focuses more on the active processing time. Both are important for process efficiency.

How can my team start tracking lead time effectively using monday.com?

Start by defining clear start and end points for your tasks or projects on a monday.com board (e.g., using status columns or date columns). Then, use Formula columns (WORKDAYS({End Date}, {Start Date})) to calculate lead time automatically. Visualize this data on Dashboards to track averages and identify trends.

Does lead time apply to Agile methodologies like Scrum and Kanban?

In Kanban, lead time (and cycle time) are key metrics for understanding flow and identifying areas for improvement. Teams often aim to reduce agile lead time. In Scrum, while not always explicitly called "lead time," the concept is relevant for understanding how long it takes for backlog items to move from idea to "Done," often within a sprint or across multiple sprints.

Can I automate lead time calculations in monday.com?

Yes, you can use Formula columns to automatically calculate lead times based on start and end dates or status changes captured by timestamps. You can also set up automations to populate these date fields when statuses change, further streamlining the tracking process.