Ever feel like your team is constantly racing against the clock, unsure how long projects really take? You’re not alone. Many teams struggle with opaque timelines and hidden inefficiencies. This is where understanding ‘cycle time’ becomes a game-changer for efficient work management.

Cycle time, a critical metric, offers a clear window into your team’s productivity by measuring the actual time spent working on tasks.

Unlike related terms like lead time or takt time, cycle time focuses specifically on the active work period, helping you pinpoint bottlenecks and streamline processes.

In this guide, we’ll break down what cycle time means for your daily work in a work management context, how to measure it, and most importantly, how you can leverage monday.com to optimize it. Let’s get started.

What is cycle time?

In its simplest form, cycle time is the total elapsed time a team spends actively working on a task, from the moment work begins until it’s ready for delivery or the next step. This includes any wait times or delays that occur *within* the active work phases of that specific task.

For example, if a designer starts a task, then waits for feedback before resuming, that feedback wait time (if part of their defined process for that task) is included in the cycle time for that design task.

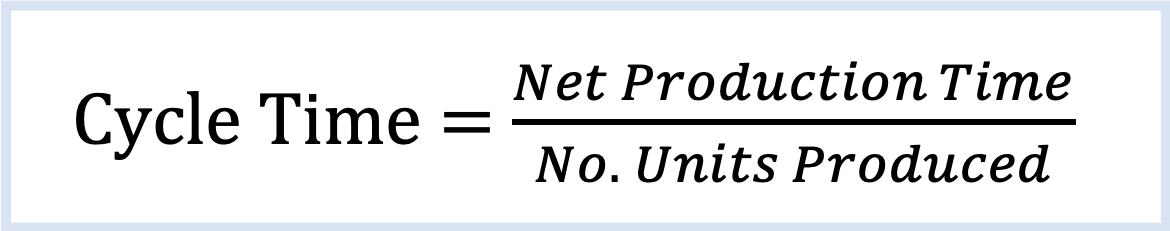

If it helps, there’s a basic formula project managers often use to calculate cycle time. That formula is:

- Cycle time (CT) = Net Production Time (NPT) / Number of Units made (U)

There’s a bit of business jargon in there, but don’t worry.

Net production time (NPT) is just a fancy way to describe the complete duration of your team’s production process. The unit that you use for NPT is normally going to be minutes, hours, days, or weeks.

Why cycle time isn’t just for manufacturing anymore

While cycle time has its roots in manufacturing, its principles are incredibly valuable in any work management scenario – from marketing campaigns and software development sprints to HR onboarding processes and customer support.

A ‘unit’ might be a completed blog post, a resolved support ticket, a designed graphic, or a coded feature. Understanding cycle time helps teams in these diverse fields improve predictability, efficiency, and throughput.

What are the benefits of calculating your cycle time?

Tracking and optimizing cycle time isn’t just an academic exercise, it delivers tangible benefits that directly contribute to your team’s success and overall business objectives.

Gain accurate project estimations and meet deadlines

If you can calculate your average cycle time for common tasks in real-time, it’ll enable you to give your customers and stakeholders realistic delivery estimates.

By giving spot-on estimates, you’ll do a better job at managing expectations and delivering what you’ve promised, when you’ve promised.

That enhances customer and stakeholder relations and gives your clients confidence in your team.

Identify and eliminate workflow bottlenecks

Consistently high cycle times, or cycle times that vary wildly for similar tasks, often point to bottlenecks in your workflow. By tracking cycle time for different stages of a process (e.g., ‘drafting’, ‘review’, ‘revisions’ for a blog post), you can pinpoint where work is slowing down and take targeted action.

Improve team productivity and resource allocation

Understanding your average cycle time allows for better team time management and resource allocation.

When you understand your cycle time, you’ll always know approximately how long it takes you to produce a unit or finish a single task.

From there, you can take a look at your current and future demand to work out whether you’ve got enough capacity and time to do the job. If not, you might need to adjust priorities, reallocate resources, or manage expectations about delivery timelines.

Enhance customer satisfaction with predictable delivery

Predictable delivery, a direct result of well-managed cycle times, leads to higher customer satisfaction. When clients know what to expect and receive quality work consistently on time, trust and loyalty grow.

Make data-driven decisions for process improvement

Cycle time data provides a quantitative basis for process improvement initiatives. Instead of relying on gut feelings, you can use historical cycle time trends to identify areas for improvement, experiment with changes, and measure their impact.

In project management, this translates to avoiding wasted effort on low-priority tasks or gold-plating deliverables beyond what’s required, ensuring resources are focused effectively.

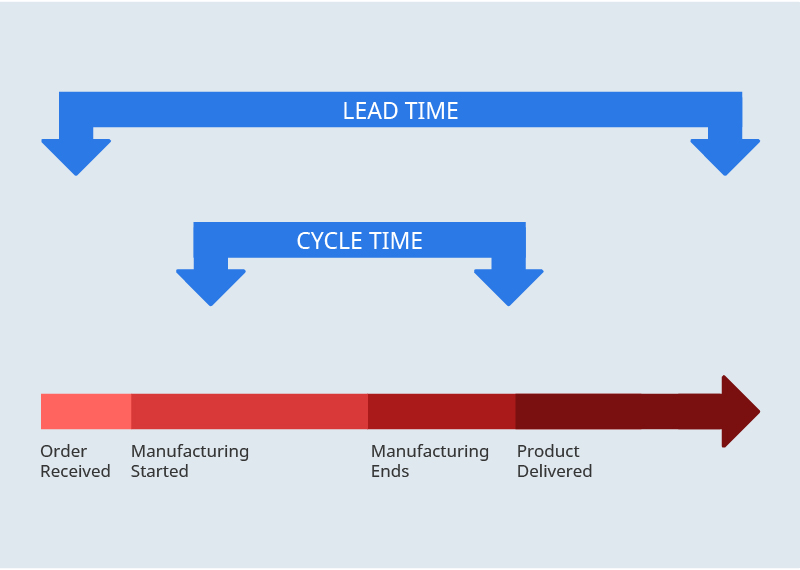

What’s the difference between cycle time and lead time?

Now that you understand why cycle time is so important, let’s clear up some common confusion with related terms like lead time and takt time. While all three relate to time and efficiency, they measure different aspects of your workflow.

Cycle time: The active work phase

Cycle time is unique because it measures how much time you spend actively working on a task or producing something. The clock for cycle time starts when your team begins an operation on a specific item or task, and it stops at the point in which that item or task is completed and ready for the next step or delivery.

Lead time: The customer’s total wait

Lead time is a little bit different. Lead time starts when a customer order or request comes in, and then it ends when you deliver the goods or services to that client or stakeholder. Lead time, therefore, includes cycle time plus any waiting time before work begins (e.g., time in a backlog queue) and any waiting time after work is completed but before delivery.

Let’s illustrate with a work management example:

Imagine a client requests a new marketing brochure on Monday. Your design team starts working on it on Tuesday and completes the design (their cycle time) in 4 hours..

However, due to other pending requests and internal reviews, the final brochure isn’t delivered to the client until Friday.

In this case, the cycle time for the design task was 4 hours, but the total lead time from request to delivery was 5 days.

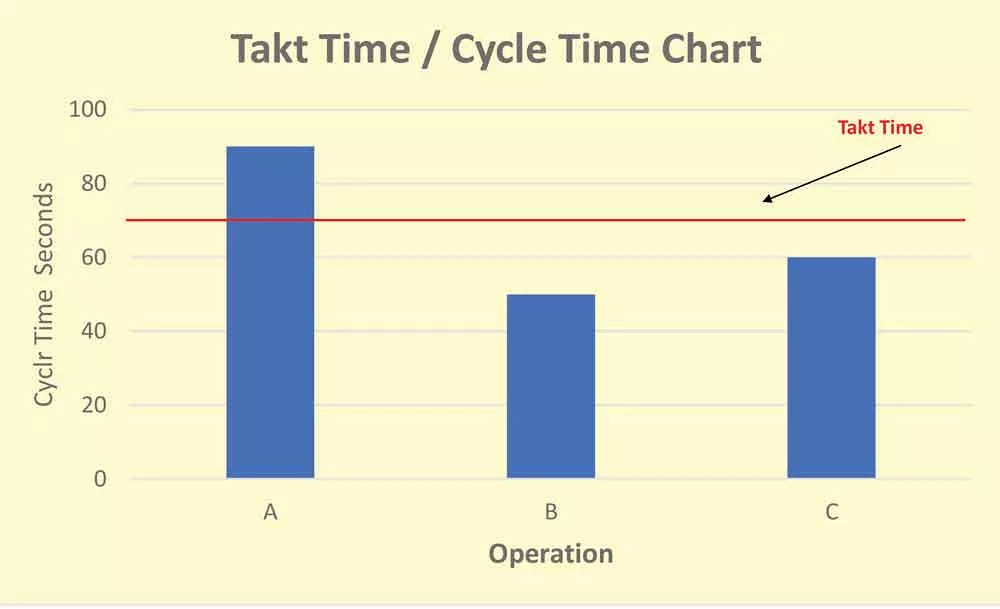

What’s the difference between cycle time and takt time?

Takt time is different from both cycle time and lead time.

While cycle time measures how long it takes you to complete a process or a task, takt time is a calculation that determines the pace at which you need to complete work to meet customer or market demand.

“Takt” is another word for “pulse” in German. Just like a heart rate, customer demand can speed up or slow down. And you’ll want to match your production (or service delivery) to suit.

By understanding the demands customers are making on your organization, you’ll be able to make sure you can always meet demand without overburdening your team or falling behind.

Takt time helps you set a rhythm for your work.

If this is all new to you, don’t stress. Again, there’s a handy-dandy formula you can use to work out your takt time. That formula is:

- Takt = available time / customer demand

For example, if your marketing team needs to produce 20 social media posts per week (customer demand) and has 40 available work hours in that week (available time), the takt time is 40 hours / 20 posts = 2 hours per post. This means, on average, a post needs to be completed every 2 hours to meet demand. Your actual cycle time for creating a post might be more or less than this.\

Simply put: cycle time is all about how long it takes to complete a task. Lead time is the total time from request to delivery. Takt time is a customer demand calculation that tells you how often a task should be completed to meet demand.

Here’s a quick table to summarize the differences:

| Cycle Time | Lead Time | Takt Time | |

|---|---|---|---|

| Starts when... | Work begins on a specific task/item. | Customer/stakeholder makes a request. | (Not applicable - it's a calculated rate) |

| Ends when... | Task/item is completed and ready for next step/delivery. | Request is fulfilled and delivered to customer/stakeholder. | (Not applicable - it's a calculated rate) |

| Measures what? | Time spent actively working on a task. | Total time customer/stakeholder waits for fulfillment. | Required pace of production/completion to meet demand. |

| Primary Goal | Improve process efficiency, reduce active work time. | Improve overall customer experience, reduce total wait time. | Synchronize production/work rate with customer demand. |

How to calculate cycle time – formula & practical examples

As mentioned earlier, the fundamental formula for average cycle time is:

Cycle Time (CT) = Net Production Time (NPT) / Number of Units (U)

Where:

- Net Production Time (NPT): The total time spent actively working on producing a batch of units or completing a set of tasks. This excludes major downtimes or periods when no work is being done on these specific items.

- Number of Units (U): The total number of completed units or tasks in that batch.

This formula gives you the *average* cycle time per unit. For more granular insights, especially in work management, you’ll often measure the cycle time for individual tasks from their actual start to actual finish.

- Define start and end points: Clearly define what signifies the “start” and “end” of a task’s cycle time. For example, does “start” mean when a task is assigned, or when someone actively begins working on it? Does “end” mean when it’s first completed, or after review and approval? Consistency is key.

- Track time: Use a reliable method to track the time spent on each task. This could be manual logging, spreadsheets, or ideally, a work management platform like monday.com with built-in time tracking features.

- Record start and finish times: For each task, note the exact date and time it started and finished according to your definitions.

- Calculate duration: Subtract the start time from the finish time to get the cycle time for that individual task.

- Analyze and aggregate: You can then analyze individual cycle times or calculate averages for similar types of tasks to understand trends and identify areas for improvement.

Example 1: Cycle time for a marketing campaign task

Let’s say your marketing team is working on creating a new landing page.

- Task: Design landing page mock-up.

- Start time: Tuesday, 10:00 AM (designer begins active work).

- End time: Tuesday, 2:30 PM (designer finalizes mock-up, including a 30-min break).

- Cycle time = 4.5 hours. (If breaks are excluded by policy, it would be 4 hours).

Example 2: Cycle time for resolving a support ticket

- Task: Resolve a customer’s technical issue.

- Start time: Wednesday, 9:15 AM (support agent picks up the ticket and starts investigation).

- End time: Wednesday, 10:00 AM (agent sends resolution to customer and closes ticket).

- Cycle time = 45 minutes.

Example 3: Cycle time for a software dev sprint task

- Task: Develop a new user authentication feature.

- Start time: Monday, Day 1, 1:00 PM (developer starts coding).

- End time: Wednesday, Day 3, 4:00 PM (feature coded, unit tested, and merged).

- Cycle time = 2 days and 3 hours (or approx. 19 working hours if following standard 8-hour workdays, excluding non-work time).

Strategies to reduce and optimize cycle time in your workflows

Understanding and calculating cycle time is the first step. The real value comes from using this information to actively reduce and optimize it.

Here are some effective strategies:

Clearly define task start and end points

Ensure everyone on the team has a shared understanding of when a task officially starts and when it’s considered complete. This consistency is crucial for accurate measurement and identifying true areas for improvement.

Limit work in progress (WIP) effectively

Encouraging team members to focus on completing current tasks before starting new ones can significantly reduce cycle times. High WIP often leads to context switching, delays, and reduced overall throughput. Using Kanban boards with WIP limits is a great way to implement this.

Streamline handoffs between team members

Handoffs are common points where delays occur. Map out your processes to identify handoff points and look for ways to make them smoother and faster. Clear communication protocols and defined responsibilities can help.

Automate repetitive tasks

Identify manual, repetitive tasks within your workflows that can be automated. Work management platforms like monday.com offer robust automation capabilities that can handle notifications, task assignments, status updates, and more, freeing up team members and reducing cycle times.

Improve task clarity and requirement gathering

Ambiguous tasks or incomplete requirements lead to rework and delays. Invest time upfront to ensure tasks are well-defined, with clear acceptance criteria, before work begins.

Foster a culture of continuous feedback and improvement

Regularly review your cycle time data with the team. Hold retrospectives to discuss what’s working, what’s not, and identify opportunities for process improvements. Encourage experimentation and learning.

Common challenges in managing cycle time (And how to overcome them)

Managing and reducing cycle time can present challenges. Here are a few common ones and how to address them:

- Inconsistent task definitions – “done” means different things to different people so cycle time data can easily get skewed. The way to solve this is to standardize task definitions and create clear “Definition of Done” (DoD) criteria for various task types. Use monday.com templates to enforce consistency.

- Hidden wait times – Time spent waiting for information, approvals, or resources can inflate cycle times. Solve this by mapping your value stream to identify all steps, including wait states. Use monday.com status columns to explicitly track “waiting for X” stages and analyze time spent in them.

- Resistance to tracking – team members might feel micromanaged if time tracking is introduced poorly. So you need to communicate the “why” behind tracking cycle time – focus on process improvement, not individual performance policing. Use monday.com’s integrated timer and automations to make time tracking a breeze.

- Scope creep – tasks growing larger than initially planned will naturally extend cycle times. Solve this by implementing clear scope management processes. Break down large tasks into smaller, manageable sub-items on your monday.com boards.

How monday.com empowers you to master cycle time

monday.com is more than just a Work OS; it’s a powerful platform that provides the tools and visibility you need to effectively track, analyze, and optimize your team’s cycle times across all types of work.

Visualizing work and tracking progress with Kanban & timeline views

monday.com’s flexible board views, such as Kanban, Gantt, and Timeline views, allow you to visualize your workflow stages clearly.

You can see where tasks are in the process, how long they’ve been in a particular stage, and quickly identify items that might be stuck, directly impacting cycle time. Some views can even display cycle time per item automatically.

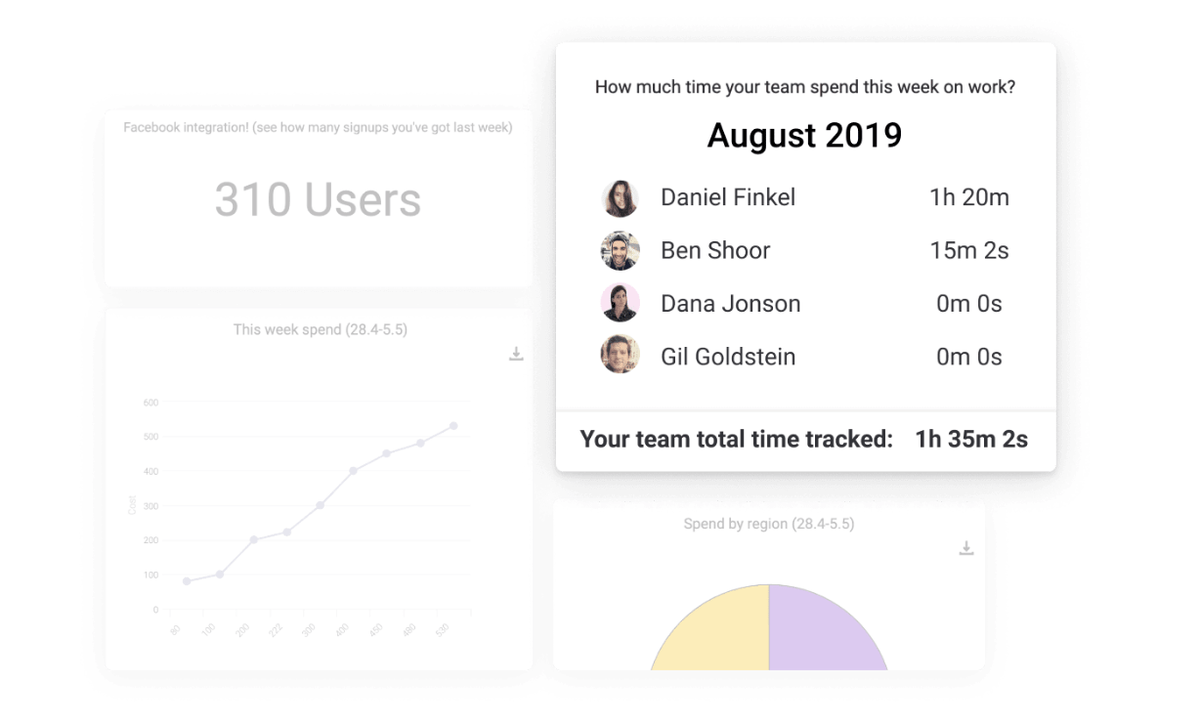

Accurate time tracking for every task

The monday.com Time Tracking Column is essential for capturing accurate cycle time data.

With our dynamic time tracking column, it’s easy to keep track of every single one of your cycle times for any given task throughout the course of a project. Making it all happen is super simple, too.

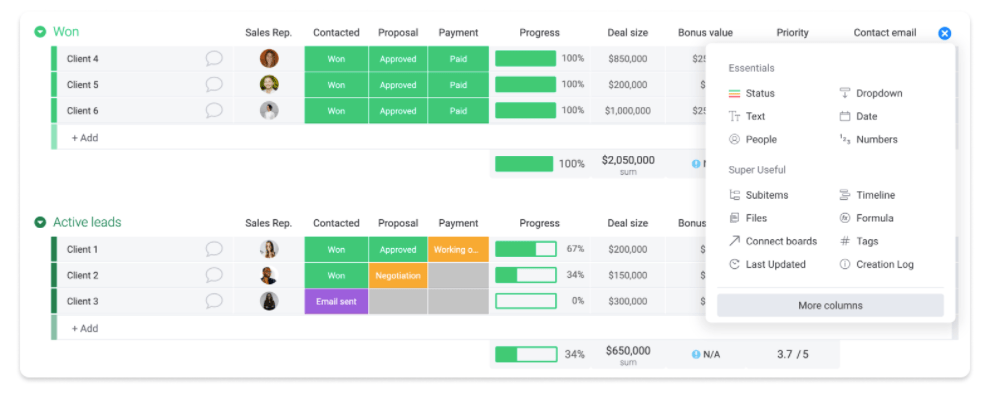

ou can easily add it to any board.

After you pick a template, you can click on the “+” icon, which is located in the top right-hand corner of your board. Then, you need to select the “More columns” option.

That will take you to your column center. There are loads of options to choose from, but right now, we only want “time tracking.”

Click on it, and you’re done. That’s it. From here on out, all you’ve got to do is click the timer to start it. You can then stop or pause that timer at any time throughout your production process.

End result: now, you’ll always know exactly how long it’s taking for each member of your team to finish each task. You can then average those cycle times as required using formula columns or dashboards.

Identifying bottlenecks with workload widgets and dashboards

But if you want to take your time management to the next level, you should really try out our Project Tracker Template.

Our dashboards allow you to build custom reports and visualize key metrics, including average cycle time, cycle time trends, and distributions. Use charts like bar charts, line graphs, or even specialized control charts (if applicable) to monitor performance.

The Workload widget helps you see team capacity, preventing overloads that can inflate cycle times.

Automating processes to speed up cycles

Reduce manual intervention and delays with monday.com’s powerful automations. Set up recipes to automatically move items to the next stage when a task is complete, notify the relevant team member, update statuses, or even start/stop timers based on status changes. This directly cuts down on idle time within your cycle.

Using monday.com templates to standardize and improve cycle times

Jumpstart your efficiency with monday.com’s extensive library of templates. Our templates, like the project tracker template or specific marketing and operations templates, are designed with efficient workflows in mind, often including pre-built structures for tracking progress and time.

These templates provide a solid foundation that you can customize to your specific needs, helping you standardize processes and inherently improve cycle times.

- Seamless integrations: monday.com integrates with 200+ tools, allowing you to connect your existing software stack and maintain a smooth flow of information, reducing delays caused by switching between disconnected systems.

- Enhanced collaboration: Features like real-time updates, comments, and notifications ensure everyone is on the same page, reducing miscommunication and speeding up feedback loops, which are crucial for shorter cycle times.

- Customizable workflows: Tailor monday.com to your exact processes. Define custom statuses, columns, and views that accurately reflect how your team works, enabling more precise cycle time tracking and optimization.

Ready to optimize your team’s cycle time?

Understanding and optimizing cycle time is fundamental to boosting your team’s efficiency, predictability, and overall performance in any work management setting.

It’s about pinpointing how long work actually takes, identifying delays, and streamlining your processes for smoother, faster delivery.

By differentiating cycle time from lead time and takt time, you gain a clearer perspective on where to focus your improvement efforts.

And with a powerful Work OS like monday.com, you have all the tools you need—from visual boards and time tracking to automation and insightful dashboards—to not just measure, but truly master your cycle times.

Stop guessing and start optimizing. Take control of your team’s efficiency and begin your journey to shorter cycle times and greater productivity. Try monday.com for Work Management free today.

FAQs

How can monday.com help automate cycle time tracking?

You can use monday.com to automate starting/stopping timers based on status changes (e.g., when a task moves to "In Progress"), automatically calculate elapsed time in a status using formula columns, and notify team members when tasks are ready for the next step, reducing manual tracking and idle time.

Is cycle time only important for repetitive tasks, or can it apply to unique projects?

Cycle time is valuable for both. For repetitive tasks, it helps establish benchmarks and identify efficiency gains. For unique projects, tracking cycle time for phases or key deliverables can improve estimation for future similar projects and highlight systemic bottlenecks.

What's the ideal cycle time for a specific type of work, e.g., marketing task?

There's no universal "ideal" cycle time, as it depends heavily on the complexity of the task, team skills, and available resources. The goal is to establish your own baseline by tracking current cycle times and then continuously strive to improve by identifying and removing inefficiencies. Use monday.com dashboards to benchmark against your own historical data.

How does improving cycle time impact team morale and prevent burnout?

Shorter, more predictable cycle times mean less firefighting, clearer expectations, and a greater sense of accomplishment as tasks move smoothly through the workflow. This can reduce stress, improve focus, and boost team morale by demonstrating that processes are efficient and workloads are manageable.

Can I track cycle time for sub-items on monday.com?

Yes! monday.com allows you to use sub-items to break down larger tasks. You can add Time Tracking columns and status columns to sub-items, enabling you to track and analyze cycle times at a more granular level, which can then roll up to the parent task.