Your operations team just committed to 3 major projects by quarter-end, sales promised faster turnaround times, and finance approved next quarter’s headcount — but can you actually deliver without burning out your team or blowing the budget? Aggregate planning is the strategic process that balances production capacity with market demand over 3-18 months, helping you make smart decisions about workforce levels, production capacity, and resource allocation before conflicts arise.

This guide covers the essential strategies, step-by-step planning process, and practical examples that turn aggregate planning from a quarterly headache into a continuous capability. You’ll discover how to build plans that adapt to changing conditions, avoid costly resource mismatches, and create the operational foundation that supports sustainable growth.

Try monday work managementKey takeaways

- Aggregate planning smooths demand fluctuations over 3-18 months, helping you avoid costly overproduction and stockouts while keeping your workforce stable.

- Level strategies work best for stable demand, chase strategies fit seasonal businesses, and mixed strategies balance multiple objectives for most real-world situations.

- Modern planning platforms provide portfolio-level insights and AI-powered analytics that enable dynamic plan adjustments and proactive risk identification across all your projects.

- Combine demand forecasts, resource constraints, inventory levels, and financial parameters to create data-driven plans that actually work in practice.

- Integrated work management platforms connect operational execution to business strategy, creating competitive advantages through improved cost control and customer service.

What is aggregate planning?

Aggregate planning is a strategic process that balances production capacity with forecasted demand over a 3–18 month horizon. Unlike detailed scheduling that focuses on specific products and daily operations, aggregate planning operates at a higher level — making decisions about overall resource allocation across product families rather than individual items.

This planning approach bridges the gap between your long-term strategy and day-to-day scheduling decisions. Organizations use aggregate planning to make informed decisions about workforce levels, production rates, inventory levels, and subcontracting needs while maintaining flexibility to respond to market changes.

The process addresses fundamental questions that shape operational performance: How many people should you employ next quarter? Should you build inventory now or increase production later? When should you use overtime versus hiring temporary workers? These decisions directly impact operational costs, customer service levels, and organizational agility.

Aggregate planning vs. capacity planning: Key differences

Aggregate planning is often confused with capacity planning — but the two serve distinct roles in operations management. Understanding their differences prevents confusion and ensures organizations address both strategic capacity decisions and tactical resource allocation.

Capacity planning determines the maximum output an organization can produce, while aggregate planning determines how to use that capacity over time to meet demand. Capacity planning addresses questions like: should we build a new facility? what equipment should we purchase? how large should our workforce be? These decisions typically have 1–5 year horizons and involve significant capital investments.

Aggregate planning operates within the capacity constraints established by capacity planning. It addresses tactical questions like: how should we use our existing capacity next quarter? should we increase overtime or hire temporary workers? when should we build inventory versus increasing production?

The relationship between these processes is hierarchical:

- Capacity planning: Sets upper bounds and maximum production capability

- Aggregate planning: Optimizes resource utilization within those bounds

- Feedback loop: Aggregate planning insights inform future capacity decisions

When aggregate planning consistently shows capacity constraints limiting performance, that signals the need for capacity planning initiatives. Conversely, capacity planning decisions must consider aggregate planning patterns to ensure new capacity aligns with actual demand patterns.

Key characteristics of aggregate planning

To fully grasp its role, it’s important to understand the unique features that define aggregate planning. These characteristics distinguish it from daily scheduling or long-term strategic planning and are crucial for making effective mid-range operational decisions.

- Time horizon: Covers 3–18 months ahead, providing enough visibility for strategic resource decisions while staying responsive to market changes

- Planning level: Focuses on product families rather than individual items, reducing complexity while maintaining strategic relevance

- Resource scope: Addresses workforce, equipment, and inventory collectively, recognizing how these resources interact and constrain each other

- Decision impact: Influences hiring decisions, overtime policies, and capacity investments that shape operational performance for months ahead

What an aggregate plan typically includes

An aggregate plan usually defines:

- Target production rates: Expected output by period at the product-family level

- Workforce plan: Core staffing levels, overtime assumptions, and temporary labor use

- Inventory targets: Planned inventory build-ups and drawdowns over time

- Capacity levers: When to use overtime, subcontracting, or shift changes

- Cost assumptions: Labor, inventory carrying, and capacity adjustment costs

How aggregate planning drives operational excellence

Organizations that master aggregate planning gain competitive advantages extending beyond simple production scheduling—particularly important as 84% of business leaders feel underprepared for future disruptions, underscoring the need for structured, mid-term planning that proactively balances capacity and demand. The process creates value through 3 interconnected capabilities that directly impact financial performance and market responsiveness.

Balancing supply and demand at scale

Aggregate planning helps you avoid the twin disasters of warehouses full of unsold products and angry customers facing empty shelves. It gives you tools to absorb demand spikes and dips through smarter inventory decisions and flexible capacity.

When demand spikes unexpectedly, organizations with strong aggregate planning processes can quickly evaluate their options — increase overtime, tap into inventory reserves, or activate subcontracting relationships based on predetermined cost structures and capacity constraints.

Cost optimization across multiple variables

Aggregate planning directly influences labor costs, inventory carrying costs, and capacity utilization — 3 of the largest operational expense categories for most organizations.

A manufacturing organization might discover that building inventory during slow periods costs less than paying overtime premiums during peak seasons, even after accounting for storage and carrying costs. A service organization might find that maintaining a slightly larger core workforce reduces the need for expensive temporary staffing during busy periods. These insights only emerge through systematic aggregate planning that evaluates multiple variables simultaneously.

Departmental alignment and strategic coherence

Aggregate planning gets everyone on the same page — from sales and production to finance and HR. Without it? Chaos. The sales team promises delivery dates your team can’t possibly hit. Finance approves headcount that doesn’t match what operations actually needs. And HR recruits on a timeline completely disconnected from your capacity crunch points.

Cross-functional collaboration becomes essential when teams work from the same aggregate plan. Sales, operations, finance, and HR make coordinated decisions that reinforce rather than undermine each other. The planning process itself becomes a forum for resolving conflicts and building consensus around realistic commitments.

3 essential aggregate planning strategies

Not every business faces the same challenges, so you’ll need to pick the right strategy for your specific situation. Here, we’ll break down 3 core approaches that operations managers can adapt to their unique market conditions and constraints. Each strategy represents a different way to balance workforce stability, inventory costs, and service levels. Most organizations use the table below to compare options before tailoring an approach to their constraints.

| Strategy | Approach | Best for | Key trade-offs |

|---|---|---|---|

| Level strategy | Maintain constant production rates and workforce levels; absorb demand fluctuations through inventory | Organizations with stable demand, predictable sales patterns, and a skilled workforce | Higher inventory carrying costs in exchange for workforce stability and predictable operations |

| Chase strategy | Adjust production and workforce levels to match demand using overtime, temporary labor, or subcontracting | Seasonal businesses or organizations with highly variable demand and flexible labor options | Lower inventory costs but higher workforce disruption, potential morale impact, and quality risks |

| Mixed strategy | Combine a stable base workforce with flexible capacity levers such as overtime or subcontracting | Most real-world organizations facing fluctuating demand and multiple operational constraints | Balances cost, service levels, and stability but requires stronger planning discipline and coordination |

Level strategy: Maintaining steady production rates

The level strategy prioritizes workforce stability by maintaining consistent production rates over time, absorbing demand fluctuations through inventory. It works best when demand is predictable and inventory carrying costs are manageable.

Organizations often choose this approach when retaining skilled labor is more valuable than minimizing inventory. However, it becomes impractical when demand volatility is high or products have short shelf lives.

Chase strategy: Matching production to demand fluctuations

The chase strategy aligns production directly with demand, minimizing inventory by adjusting capacity through overtime, temporary labor, or subcontracting. It’s most effective in highly seasonal environments where demand swings make inventory storage impractical.

The trade-off is workforce disruption. Frequent hiring and layoffs can impact morale, quality, and long-term labor availability — risks organizations must weigh carefully.

Mixed strategy: Combining elements for real-world complexity

Most organizations rely on a mixed strategy that combines stable base capacity with flexible options like overtime, temporary labor, or subcontracting. This approach balances cost control, workforce stability, and service levels across changing demand conditions — especially relevant given that manufacturing capacity utilization stood at 76.9% in June 2025

While mixed strategies offer flexibility, they require stronger planning discipline to manage trade-offs across multiple variables — making portfolio-level visibility and scenario modeling essential.

Try monday work managementCritical inputs for successful aggregate planning

Aggregate planning quality depends entirely on input accuracy and completeness. Organizations that treat planning as a data-driven process consistently outperform those relying on intuition or incomplete information. The following 4 input categories form the foundation of effective aggregate planning.

Demand forecasts and market analysis

Demand forecasts form the foundation of aggregate planning, providing the target that all resource allocation decisions aim to meet. To build a reliable forecast, you must synthesize information from several key areas that provide a complete picture of market dynamics.

- Historical sales data: Reveals seasonal patterns and trends

- Market intelligence: Captures competitive dynamics and economic conditions

- Promotional impacts: Accounts for marketing campaigns and pricing changes

- Customer insights: Incorporates sales team knowledge about major accounts

Forecast accuracy directly impacts planning effectiveness. Overestimated demand leads to excess inventory and underutilized capacity, while underestimated demand results in stockouts and missed revenue opportunities. Organizations increasingly use AI-powered forecasting on platforms like monday work management to improve prediction reliability by processing larger datasets and identifying complex patterns that traditional methods miss.

Resource availability and constraints

Understanding current workforce capabilities, equipment capacity, supplier limitations, and financial resources determines which planning strategies are feasible. Workforce analysis examines not just headcount but skills, productivity levels, and availability. Equipment evaluation considers effective capacity accounting for maintenance requirements, changeover times, and quality considerations.

Resource constraints often determine planning strategy more than demand patterns do. An organization with flexible workforce options and reliable subcontractors can pursue chase strategies, while one with specialized equipment and skilled labor requirements gravitates toward level strategies despite higher inventory costs.

Inventory levels and storage capacity

Current stock positions and warehouse limitations influence production planning decisions by determining how much inventory buffer the organization can maintain. Storage capacity creates hard constraints on level strategies — you cannot build inventory indefinitely during slow periods if warehouse space runs out.

The relationship between inventory costs and service level targets shapes planning decisions. Organizations promising high service levels need larger inventory buffers than those willing to accept occasional stockouts. Aggregate planning at the product family level helps avoid mismatches by ensuring production plans align with demand patterns across the entire portfolio.

Financial parameters and budget limits

Cost structures, budget constraints, and investment policies shape planning options by determining which strategies the organization can afford. Labor rates, overtime premiums, and temporary worker costs influence the relative attractiveness of level versus chase strategies. Inventory carrying costs determine how much inventory buffer makes economic sense.

Budget constraints may limit planning options regardless of operational preferences. An organization facing cash flow constraints cannot build large inventory positions even if that would optimize production efficiency. Financial planning cycles must align with aggregate planning horizons to ensure budgets support operational plans.

How to build an aggregate plan in 5 steps

Building an effective aggregate plan requires a systematic approach that moves from demand analysis through capacity evaluation to strategy selection and implementation. This structured process ensures you consider all critical factors and create a plan that balances operational efficiency with strategic objectives.

Step 1: Analyze historical and projected demand

Start with comprehensive demand analysis combining historical data with forward-looking forecasts. Gather sales data for at least 2 years, organizing it by product family and time period to reveal seasonal patterns, growth trends, and demand variability.

Involve sales and marketing teams in forecast development to incorporate market intelligence that historical data cannot capture. Sales teams know about major customer plans and competitive threats. Marketing teams understand promotional impacts and new product introductions. The forecast should extend across the entire planning horizon with monthly or quarterly granularity.

Step 2: Evaluate current production capacity

Capacity assessment examines workforce capabilities, equipment availability, and process constraints to determine how much the organization can produce under different scenarios. Calculate effective capacity under different operating scenarios — normal operations with regular time only, operations with moderate overtime, and maximum capacity with full overtime and temporary workers.

Identify bottlenecks that limit overall system capacity. A manufacturing process might have adequate workforce and most equipment, but one critical machine limits total output. Understanding these constraints prevents planning decisions that look good on paper but cannot be executed in practice.

Step 3: Select your planning strategy

Choose between level, chase, or mixed strategies based on cost structures, workforce flexibility, and market requirements. Organizations with stable demand and high inventory carrying capacity lean toward level strategies. Those with highly seasonal demand and flexible labor markets gravitate toward chase strategies.

Most organizations find that mixed strategies best balance multiple objectives. Model the total cost of different approaches, including labor costs, inventory costs, and service costs. The lowest total cost strategy becomes the starting point, adjusted for strategic considerations like workforce stability or customer relationship priorities.

Step 4: Develop multiple scenario plans

Create aggregate plans for optimistic, expected, and pessimistic demand scenarios. This scenario analysis reveals how sensitive the plan is to forecast errors and identifies trigger points where the organization should shift strategies.

Model different capacity and cost assumptions to understand how changes in key parameters affect planning decisions. What if overtime costs increase? What if temporary worker availability decreases? This sensitivity analysis shows which planning decisions are robust across different conditions.

Step 5: Implement and monitor your chosen plan

Implementation requires communicating the plan to all stakeholders — operations teams who execute it, sales teams who need to understand capacity constraints, finance teams who track costs, and HR teams who manage workforce changes. Each group needs to understand not just what the plan requires but why those decisions were made.

Establish performance monitoring systems that track actual results against plan. Regular review cycles compare actual performance to plan and identify variances requiring attention. The monitoring process should distinguish between random variation and systematic deviations that signal the need for plan adjustments.

Try monday work managementHow to adapt aggregate planning for a digital-first world

Traditional aggregate planning developed in an era of stable markets and monthly planning cycles. Today’s dynamic business environment demands more responsive, data-driven planning processes that adapt quickly to changing conditions. Digital transformation enables 3 key capabilities that modernize aggregate planning.

Real-time plan adjustments and dynamic replanning

Digital platforms enable continuous monitoring and rapid plan modifications, shifting aggregate planning from a monthly batch process to a dynamic, event-driven activity. Organizations track actual performance against plan in real-time, identifying deviations as they occur rather than discovering them weeks later.

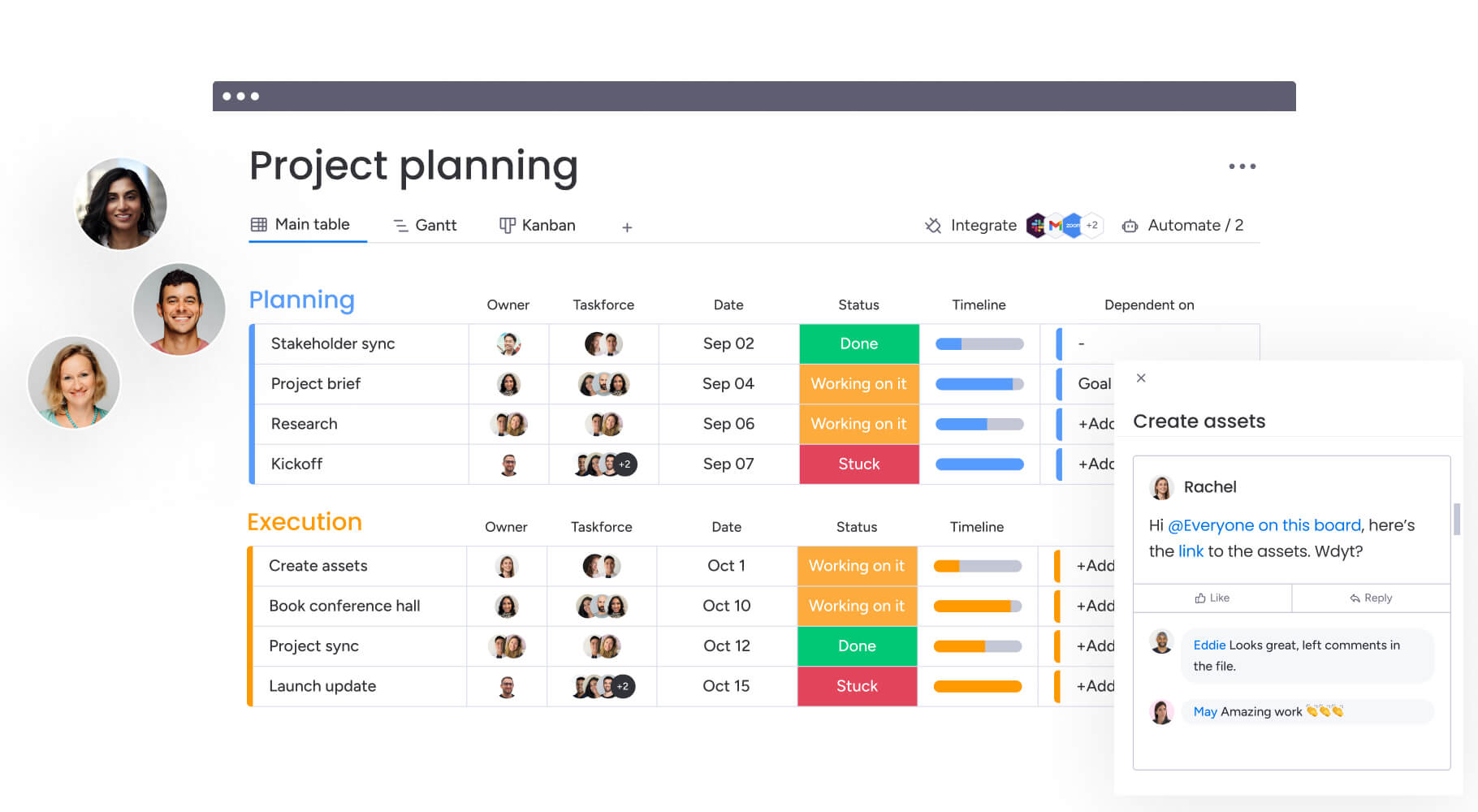

When significant changes occur — a major customer order, a supplier disruption, an unexpected demand spike — operations managers immediately evaluate the impact and make necessary adjustments. An integrated work management platform provides this real-time visibility by connecting project execution data with planning systems, making it a single source of truth that keeps stakeholders aligned as plans evolve.

AI-enhanced demand forecasting and predictive analytics

Machine learning algorithms process larger datasets and identify complex patterns that traditional forecasting methods miss. AI-powered forecasting systems automatically incorporate new data as it becomes available, updating predictions continuously rather than requiring manual forecast revisions.

The benefits extend beyond accuracy to include automated forecast updates and exception-based management. Instead of forecasters spending time updating routine predictions, AI handles the standard forecasting work while humans focus on exceptions and strategic decisions. Predictive analytics capabilities enable organizations to anticipate planning issues before they become problems, giving operations managers time to take preventive action.

Collaborative planning across distributed teams

Cloud-based platforms enable global teams to participate in planning processes regardless of location. Operations managers in different regions contribute local market intelligence, capacity information, and constraint data to the aggregate planning process, creating plans that reflect the full complexity of global operations.

Shared visibility into planning assumptions, constraints, and decisions ensures all stakeholders work from the same information. When sales, operations, finance, and HR teams see the same data and understand the same trade-offs, they make coordinated decisions that reinforce rather than undermine each other.

Aggregate planning examples across industries

Aggregate planning principles adapt to different industry characteristics, with each sector facing unique challenges that shape how they approach capacity and demand balancing. These real-world examples demonstrate how organizations apply aggregate planning strategies to their specific operational contexts.

Manufacturing: Seasonal production planning

A toy manufacturer preparing for holiday demand faces highly seasonal demand, with most annual sales occurring in the October–December quarter. The aggregate planning challenge is balancing the cost of carrying inventory against the cost and risk of trying to produce everything during peak season.

The manufacturer uses a mixed strategy combining level production with chase capacity:

- January through August: Maintain steady production at reduced capacity, building inventory of popular items with predictable demand

- September through December: Increase production using overtime and subcontract specialized components to handle the final demand surge

This approach provides workforce stability during most of the year while maintaining flexibility to meet peak demand without excessive inventory carrying costs.

Service industries: Workforce capacity management

A customer service call center experiences daily, weekly, and seasonal demand patterns — higher call volumes on Mondays, during business hours, and during tax season. Unlike manufacturing, they cannot build inventory to buffer demand variations, so workforce capacity must closely match demand patterns.

The call center uses a sophisticated mixed strategy combining:

- Full-time core staff: Sized for base demand levels

- Part-time flexible workers: Added during predictable peak periods

- Cross-trained employees: Shift between service lines based on demand

- Work-from-home agents: Provide surge capacity during unexpected spikes

The aggregate plan specifies how many workers of each type to schedule for different periods, balancing service level targets against labor costs.

Technology companies: Project portfolio planning

A software development company manages multiple client projects simultaneously, each requiring different skill combinations at different times. The aggregate planning challenge is matching available technical resources to project demands while maintaining utilization targets and delivery commitments.

The company’s aggregate planning process operates at the portfolio level, forecasting resource demand by skill type across all projects for the next 12 months. The plan addresses constraints through:

- Hiring: For sustained demand increases in specific skills

- Contractor use: For temporary peaks or specialized requirements

- Skill development: Cross-training to increase workforce flexibility

- Project prioritization: When resource constraints require trade-offs

This portfolio-level visibility prevents over-committing resources and ensures the company can deliver on existing commitments.

Elevate your aggregate planning with monday work management

Effective aggregate planning requires integrated visibility across projects, resources, and timelines — capabilities that traditional planning methods often lack. Spreadsheet-based planning creates fragmented views where operations managers manually compile data from multiple sources, struggling to maintain current information as projects evolve and priorities shift.

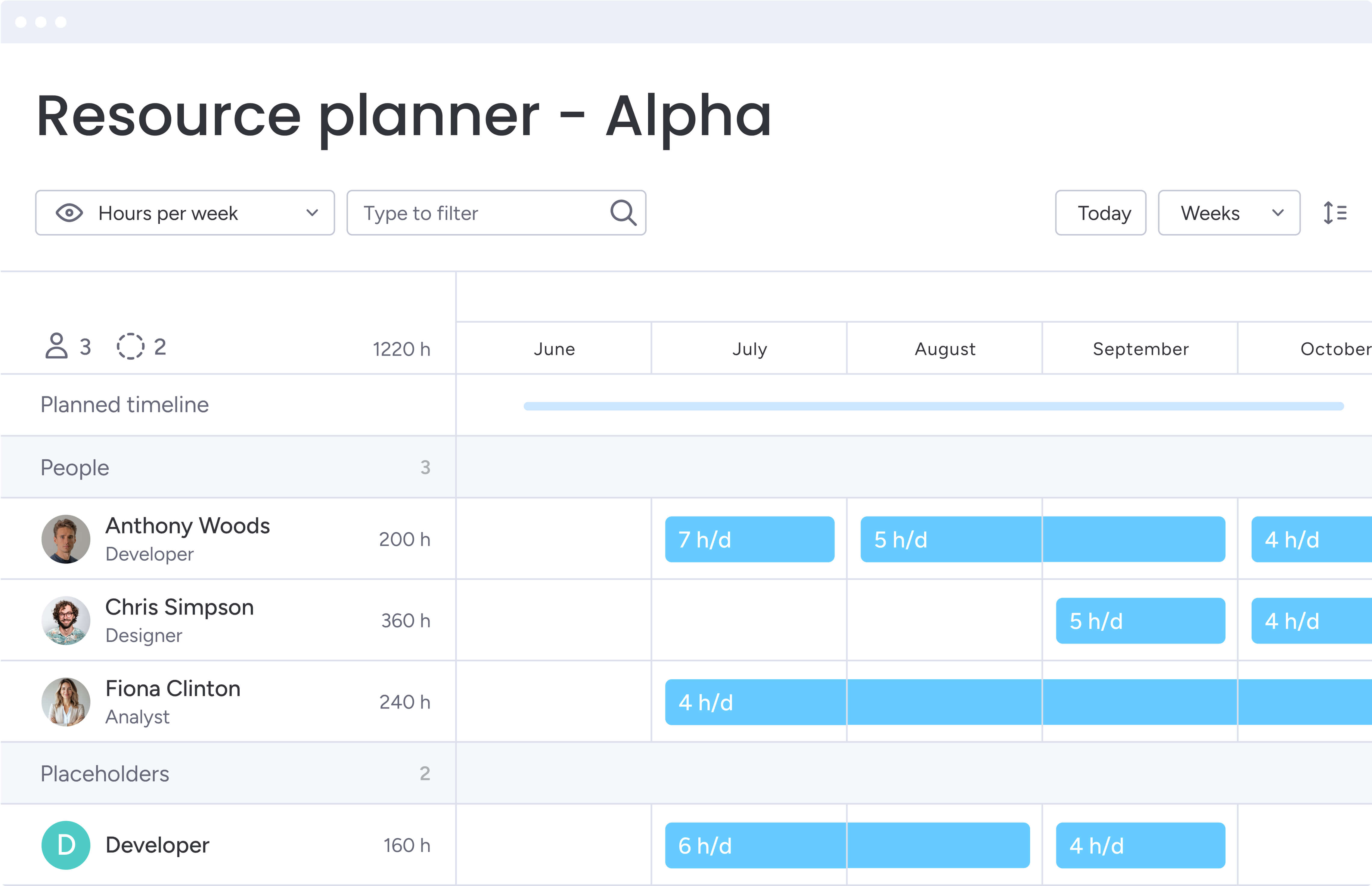

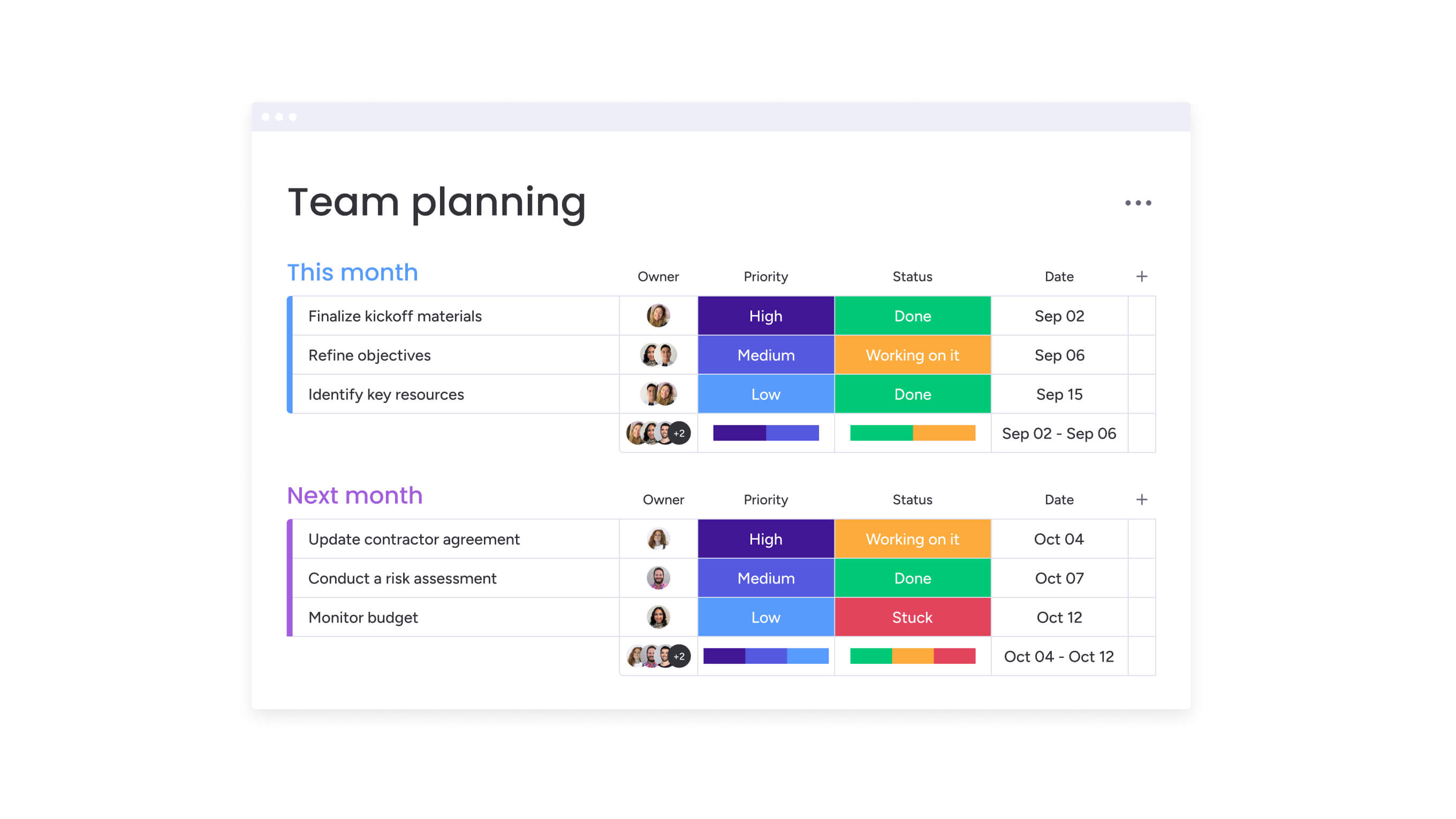

Transform aggregate planning from a periodic exercise into a continuous capability with monday work management’s portfolio management features, which provide cross-project visibility by consolidating resource allocation, project progress, and capacity utilization data in one platform. Operations managers see how resources are deployed across all initiatives, identifying patterns and constraints that would remain hidden in department-level reporting.

Real-time dashboards and reporting features enable continuous monitoring of resource utilization, project progress, and capacity constraints. When actual results deviate from plan, the dashboard immediately reflects the change, enabling rapid response. Visual portfolio management features help operations managers see resource allocation patterns and identify potential bottlenecks before they impact delivery.

To move from theory to execution, you need a platform that centralizes data and facilitates collaboration across teams. monday work management is designed with powerful capabilities that directly support the entire aggregate planning lifecycle.

- Portfolio visibility: Real-time view of resource allocation across all projects

- Workload management: Visual representation of team capacity and utilization

- Automated workflows: Streamlined resource request and approval processes

- Predictive analytics: AI-powered identification of planning conflicts and risks

- Cross-functional collaboration: Shared workspace for planning team coordination

- Integration capabilities: Connections to forecasting, financial, and HR systems

AI-powered capabilities help teams identify demand patterns, surface capacity risks, and highlight potential conflicts earlier. Automated monitoring can also flag workload imbalances and suggest resource adjustments based on real-time conditions.

Transform your operational planning into competitive advantage

Aggregate planning connects operational execution to business strategy, helping organizations balance capacity and demand with confidence. When done well, it reduces costs, improves service levels, and enables faster, more informed responses to change.

With monday work management, aggregate planning is unified in one platform where teams can define success metrics, track performance with dashboards, and leverage AI-powered insights for smarter decisions. From resource allocation to scenario modeling, the platform helps teams work faster, reduce risk, and deliver consistently high-quality outcomes at scale.

Try monday work managementFAQs

How long should an aggregate planning horizon be?

Aggregate planning horizons typically range from 3 to 18 months, with most organizations using 6–12 month planning periods. The optimal horizon depends on your industry's demand predictability, production lead times, and business cycle characteristics. Industries with long lead times or seasonal patterns need longer horizons, while those with rapid market changes benefit from shorter, more frequently updated plans.

Can aggregate planning work for service industries?

Aggregate planning works for service industries by focusing on workforce capacity rather than production output. Service organizations use aggregate planning to match staffing levels with demand patterns, manage seasonal fluctuations, and optimize resource utilization across different service lines. The principles remain the same — balancing capacity with demand — but the focus shifts to labor management rather than inventory.

How often should organizations update aggregate plans?

Most organizations update their aggregate plans monthly or quarterly, though some industries require more frequent adjustments based on demand volatility and planning complexity. The update frequency should align with your ability to implement changes effectively. More frequent updates only add value if you can actually adjust operations in response to new information.

What role does AI play in modern aggregate planning?

AI enhances aggregate planning through improved demand forecasting, automated risk detection, and optimized resource allocation recommendations. AI-powered platforms process larger datasets, identify complex patterns in demand and capacity utilization, and provide real-time insights that enable more responsive and accurate planning decisions than traditional manual approaches.

How does aggregate planning connect to S&OP processes?

Aggregate planning serves as a key component of Sales and Operations Planning (S&OP), providing the tactical execution framework for strategic S&OP decisions. While S&OP focuses on high-level business alignment between sales forecasts and operational capabilities, aggregate planning translates those strategic decisions into specific resource allocation and production plans that guide month-to-month operations.

What software platforms enhance aggregate planning?

Modern aggregate planning benefits from integrated work management platforms that provide real-time visibility, automated data collection, and collaborative planning capabilities. Platforms like monday work management offer portfolio-level insights and AI-powered analytics that traditional spreadsheet-based planning cannot match, enabling dynamic plan adjustments and proactive risk identification.