Your team just spent 3 hours in a meeting trying to figure out why the product launch missed its deadline — and everyone’s pointing fingers at different culprits. The marketing manager blames delayed assets, the developer points to scope creep, the project lead mentions resource constraints. You’re looking at symptoms, not the actual problem.

This guide shows you how the 5 Whys template cuts through the noise by asking one simple question repeatedly: “Why?” You’ll learn when to use it (and when not to), how to build templates that lead to solutions that stick, and see real examples from different industries — plus common mistakes that derail analysis and how monday work management streamlines the entire process from investigation to implementation.

Try monday work managementKey takeaways

- The 5 Whys method helps you dig past surface symptoms to discover the actual process breakdowns, communication gaps, or system failures you can fix permanently.

- Focus on fixing systems rather than blaming people — examining why processes allowed mistakes creates lasting improvements and psychological safety.

- Choose 5 Whys for operational issues and recurring problems with clear cause-effect chains, while using other methods for complex multi-factor situations.

- Always verify your root cause by testing whether fixing the identified issue would actually prevent the original problem from happening again.

- Embedding root cause investigations directly into your existing workflows, monday work management offers automated tracking, trend visibility across analyses, and collaborative boards that turn insights into implemented solutions.

What is the 5 Whys root cause analysis method?

The 5 Whys is exactly what it sounds like: asking “why” repeatedly until you get to the heart of what’s really happening. Rather than settling for the first reasonable-sounding answer, you keep digging until you find something you can actually fix.

The approach transforms reactive problem-solving into proactive organizational learning. Solutions address fundamental breakdowns rather than temporary symptoms, creating lasting improvements that prevent problems from recurring.

Origins of the 5 Whys in Toyota and lean manufacturing

Sakichi Toyoda developed the 5 Whys technique at Toyota as part of the company’s lean manufacturing philosophy. The principle was simple: stopping production to solve problems completely was more effective than repeatedly fixing the same issues.

The method has since expanded far beyond automotive manufacturing. Healthcare, software development, customer service, and operations teams across virtually every industry now use this systematic approach to problem-solving. What makes it powerful is its simplicity — any team can start using it immediately without specialized training or complex software.

How the 5 Whys technique works

The mechanics are straightforward. Teams start with a problem statement, ask “why” to identify the immediate cause, then ask “why” again about that cause. This chain continues until you reach a root cause you can address through process changes, resource allocation, or system improvements.

For example, here’s how a typical analysis might progress when a website crashes:

- Why 1: The server was overloaded

- Why 2: Too many users accessed the site simultaneously

- Why 3: A marketing campaign launched without IT notification

- Why 4: No communication protocol exists between marketing and IT

- Why 5: Cross-department workflows were never formally established

Note: The number “5” serves as a guideline rather than a strict rule. Some problems require only 3 iterations, while complex issues may need 7 or more questions to reach actionable root causes. The key is continuing until you find something you can actually change to prevent recurrence.

5 Whys vs. the fishbone diagram and other methods

Different root cause analysis methods serve different problem types, team sizes, and time constraints. Understanding when to use each approach helps you select the right method for your situation and get to solutions faster.

The 5 Whys excels in speed and simplicity. Teams can conduct effective analyses during brief meetings without extensive training or specialized software. More complex methods require dedicated workshops and sophisticated facilitation.

Key benefits of the 5 Whys analysis template

Teams that use the 5 Whys consistently solve problems faster, build solutions that last, and get sharper at spotting issues before they escalate. This small time investment saves countless hours of fixing the same problems over and over.

Greater speed and simplicity for teams

Teams complete most 5 Whys analyses in under 30 minutes without specialized training or complex software. This speed advantage is crucial, particularly because implementing a standardized root cause analysis can cut investigation time from 31 to 13 days and significantly reduce recurring safety events. This contrasts sharply with root cause analysis methods that require days of data gathering, statistical analysis, or multi-day workshops.

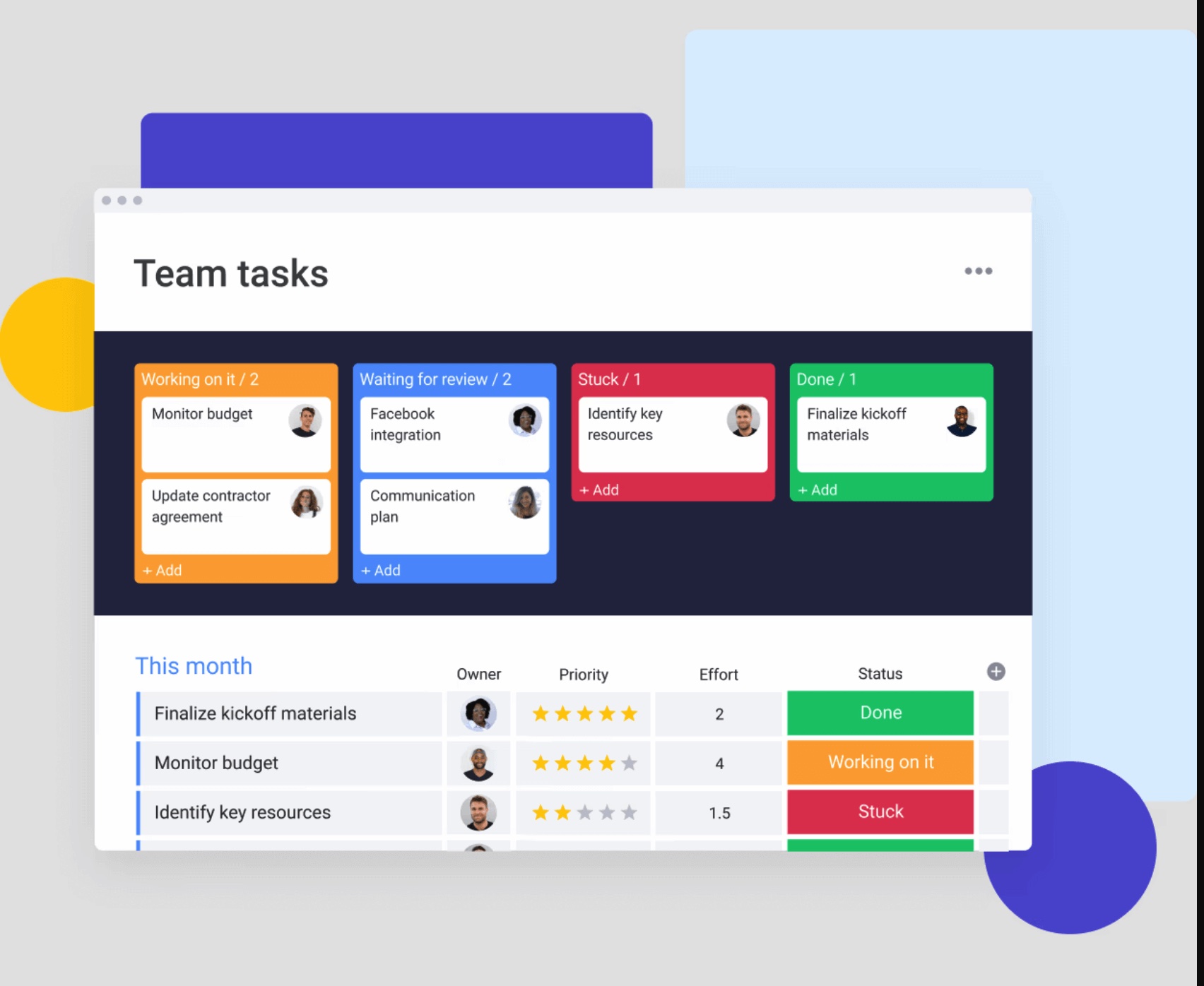

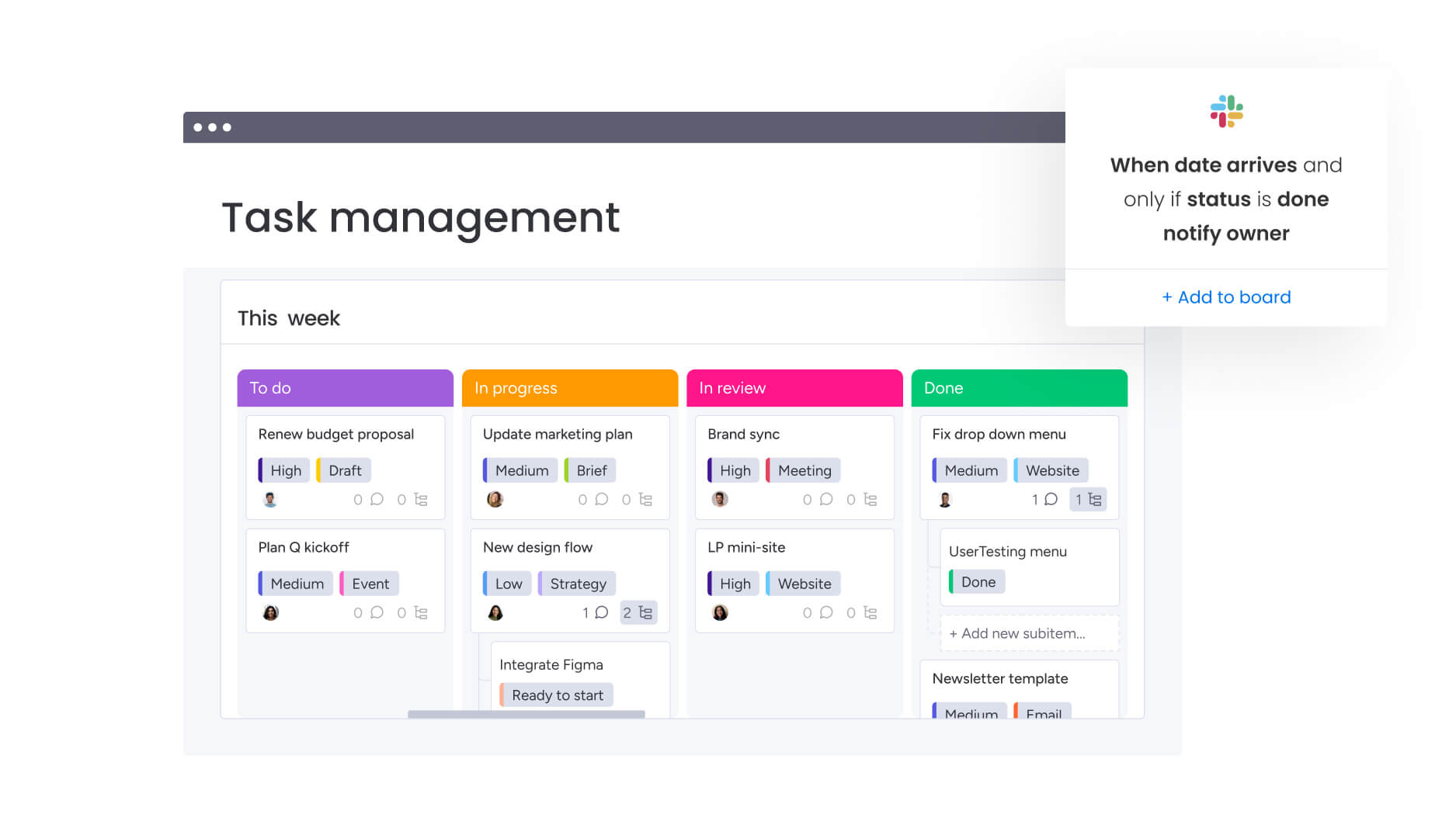

The beauty of simple questions? Anyone can ask them. Your marketing director, ops manager, and customer service lead can all jump in without learning jargon or complicated frameworks first. Teams using collaborative boards on monday work management can conduct real-time 5 Whys sessions, with participants adding insights and evidence directly into the analysis as discussions progress.

Enhanced problem understanding

It stops your team from slapping on quick fixes that feel good today but leave the real problem lurking for tomorrow. Consider when customer support ticket volume increases — surface-level solutions might involve hiring additional staff or extending service hours.

A 5 Whys analysis reveals that inadequate product documentation generates unnecessary support requests. Addressing this root cause through improved documentation reduces ticket volume permanently while also improving customer experience. This deeper understanding leads to solutions that prevent recurrence rather than merely managing symptoms.

Cost-effective continuous improvement

Preventing recurring problems saves significantly more resources than repeatedly fixing symptoms. Studies demonstrate that continuous-improvement culture yields durable, quantifiable gains, with some organizations reporting production increases of over 60% and cost reductions of 20% after embedding lean problem-solving methods.

The method requires minimal investment in training or technology while delivering measurable results, as teams only need a structured template and facilitation guidelines to begin. Organizations using monday work management amplify this cost-effectiveness by automating pattern detection across multiple analyses. The platform helps identify systemic issues that individual problem-solving sessions might miss, turning isolated fixes into organizational improvements.

Greater accountability and culture development

The 5 Whys process focuses on system improvements rather than individual blame. This creates psychological safety for honest problem analysis. When teams know the goal is fixing processes rather than finding fault, they share information more openly and identify issues more accurately.

Regular practice develops stronger analytical thinking skills across the organization. Team members begin recognizing root causes proactively rather than waiting for problems to escalate. This cultural shift transforms reactive firefighting into proactive problem prevention.

Try monday work managementWhen to use the 5 Whys template

The 5 Whys delivers optimal results for specific problem types and organizational contexts. Understanding these boundaries helps teams choose the right analytical approach and avoid wasting time on methods that don’t match their situation.

Ideal problems for 5 Whys analysis

The method works best when problems exhibit certain characteristics that align with its linear questioning approach. Here are the scenarios where 5 Whys analysis provides the most value:

- Linear cause-effect relationships: Problems where one factor leads directly to another create the straightforward progression the 5 Whys requires

- Operational issues: Process breakdowns, quality problems, and service failures typically have identifiable root causes in procedures, resources, or communication

- Recurring problems: Issues that keep happening despite previous fixes signal that earlier solutions addressed symptoms rather than root causes

- Time-sensitive situations: When problems actively impact operations or customers, teams need quick analysis to prevent further damage

- Cross-departmental issues: Problems requiring input from multiple teams benefit from the 5 Whys’ collaborative structure

A software company experiencing increased customer churn might use the 5 Whys to discover that poor onboarding experiences stem from inadequate training materials. This happens because product updates aren’t communicated to the documentation team, which occurs because no formal process connects product development and customer success functions.

Note: The 5 Whys is strongest for linear cause-effect issues. When multiple independent causes are involved — or when technical or probabilistic modeling is required — use a fishbone diagram, Pareto analysis, or fault tree analysis instead.

5 steps for creating a 5 Whys worksheet

A structured process ensures teams conduct thorough, focused analysis that leads to actionable solutions. Each step builds on the previous one to create a logical progression from problem identification to verified root cause to implementation plan.

Want a ready-made worksheet your team can use immediately? Start with a structured 5 Whys template inside monday work management.

Step 1: Define the problem statement

Effective problem statements are specific, observable, and measurable. They describe exactly what happened, when it occurred, where it took place, and what impact it created. Vague statements provide no starting point for analysis.

The formula “What happened + When + Where + Impact” creates problem statements that focus analysis effectively:

- Weak: Our website has problems

- Strong: Website load times increased from 2 seconds to 8 seconds on November 15th, causing a 35% increase in cart abandonment

Teams should gather relevant data, metrics, and context before beginning the questioning process. Organizations leveraging monday work management’s dashboards can quickly access historical data, performance trends, and impact metrics to create well-defined problem statements.

Step 2: Ask your first why

The first “why” identifies the most immediate, direct cause of the stated problem. This is the factor that, if removed, would have prevented this specific instance from occurring.

Focus on what directly triggered the issue rather than jumping to deeper systemic causes. For the website performance problem above, the first why might be “Why did load times increase to 8 seconds?” with the answer “The database queries took significantly longer to execute.”

This answer is specific, verifiable, and directly explains the observed symptom. Avoid the temptation to skip obvious intermediate steps or assume you already know the root cause.

Step 3: Build the why chain

Each subsequent “why” should logically connect to the previous answer, creating a chain of causation that moves progressively deeper into organizational systems and processes.

For the database performance issue, the chain might continue:

- Why did database queries take longer? The database hadn’t been optimized for 6 months

- Why wasn’t it optimized? The database maintenance schedule wasn’t being followed

- Why wasn’t the schedule followed? No automated reminders existed and the responsible team member left the company

Teams recognize they’ve reached a root cause when they identify fundamental breakdowns in processes, resources, communication, or systems. AI capabilities in monday work management can analyze the questioning chain and flag potential logical gaps or suggest alternative paths when the progression seems to stall.

Step 4: Verify the root cause

Validation confirms that the identified root cause actually explains the original problem and that addressing it would prevent recurrence. The “reverse test” provides straightforward validation: if you completely fixed this root cause, would it prevent the original problem from happening again?

For the database example, if database maintenance were integrated into the standard IT workflow with automated tracking and reminders, would that prevent future performance degradations? If yes, you’ve likely found a true root cause. If the answer is “maybe” or “partially,” continue the analysis.

Step 5: Create your action plan

Effective action plans translate root cause insights into specific, implementable solutions that prevent recurrence. Each action item should be specific, measurable, achievable, relevant, and time-bound.

The most effective action plans tackle both today’s fire and tomorrow’s prevention — giving you quick wins and lasting solutions.

- Immediate: Optimize the database and restore performance

- Preventive: Integrate maintenance into IT workflow system with automated reminders

- Long-term: Create backup coverage for critical maintenance tasks

Assign ownership for each action item to specific individuals. Teams using monday work management can transform action items into trackable projects automatically, with assigned owners, deadlines, dependencies, and progress monitoring integrated into existing workflows.

Essential elements of an effective 5 Whys template

A good template gives your team just enough structure to stay focused without boxing them in. It’s like having guardrails that keep you on track while still letting you explore what matters for your specific situation.

A strong 5 Whys template balances structure with flexibility — capturing enough detail to support analysis without slowing teams down.

Problem description section

Comprehensive problem documentation captures the context that team members need to understand the situation. This becomes especially important for those who weren’t present during the original incident. Essential fields include:

- Problem statement: The specific, measurable description of what went wrong

- Date and time: When the problem was first detected and how long it persisted

- Affected systems: Which parts of the organization experienced impact

- Impact assessment: Quantified effects on customers, revenue, or operations

- Stakeholders involved: Teams, departments, or individuals affected by the problem

This documentation serves multiple purposes beyond immediate analysis. It creates organizational memory for future reference, enables pattern detection across multiple incidents, and provides evidence for solution prioritization.

The 5 why cascade structure

The visual layout makes the questioning chain easy to follow. Each “why” and corresponding answer should be visually connected to show logical progression. Effective templates use cascading or flowchart formats that make the analysis path accessible.

Key structural elements include:

- Numbered levels: Each questioning level labeled (Why 1, Why 2, etc.)

- Visual distinction: Answers formatted differently from questions

- Explicit connections: Links between each answer and the next question

- Multiple paths: Space for exploring different causal branches

- Preserved history: Dead-end paths retained to show the analytical process

monday work management’s board views provide multiple visualization options. Teams can choose from linear lists to Kanban-style cascades to timeline views that show how different causal factors interact temporally.

Root cause summary box

A dedicated section states the identified root cause and the reasoning behind this conclusion. Write this in plain language that stakeholders outside the analysis team can understand.

The summary should state the root cause in a single sentence, explain why this qualifies as a root cause rather than an intermediate factor, and reference the verification process and supporting evidence.

Corrective action tracker

Action planning and follow-up elements ensure that analysis leads to implementation rather than remaining theoretical. Essential tracking fields help teams move from insight to action:

- Specific actions: Concrete steps that will address the root cause

- Assigned owners: Named individuals responsible for each action

- Target dates: Realistic deadlines with interim milestones

- Success metrics: Measurable indicators demonstrating solution effectiveness

- Status tracking: Current progress, blockers, and completion percentage

Automation capabilities in monday work management can trigger action item creation automatically when root causes are identified. The platform assigns work based on problem type or department, sends reminders as deadlines approach, and escalates overdue items to managers.

Try monday work managementReal 5 Whys examples for different industries

Concrete examples demonstrate how the method applies across different contexts. These reveal both universal principles and context-specific considerations that teams must navigate.

Manufacturing process failure

A medical device manufacturer experienced a sudden increase in product defects. The analysis revealed how systematic process gaps, not individual errors, created the problem.

Problem Statement: On January 12, 2026, 45 units from production line B failed seal integrity testing, representing a defect rate of 4.5% compared to the standard 0.2%, requiring full batch quarantine.

The questioning chain progressed:

- Why did seals fail? The sealing temperature was 15 degrees below specification

- Why was temperature too low? The heating element wasn’t reaching target despite correct control readings

- Why wasn’t it reaching target? The temperature sensor had drifted out of calibration

- Why had it drifted? The sensor exceeded its calibration interval by 3 months

- Why did it exceed the interval? The calibration system didn’t include automated alerts for line B equipment

Root Cause: New equipment wasn’t integrated into the preventive maintenance and calibration tracking system.

The solution wasn’t “remember to calibrate sensors” but rather “build systems that make forgetting impossible.”

Customer service issue

A SaaS company saw support ticket volume increase dramatically. Their analysis uncovered coordination gaps between departments.

Problem Statement: Between September and October 2025, support ticket volume increased from 800 to 1,280 per month while resolution time increased from 4 to 11 hours, causing customer satisfaction to drop from 4.3 to 3.6.

The analysis revealed:

- Why did volume increase? A new feature launched in September generated confusion

- Why did it generate confusion? Users couldn’t find configuration instructions

- Why weren’t instructions available? Documentation was created but not linked properly

- Why wasn’t it linked? Product and documentation teams worked on separate timelines

- Why separate timelines? No formal process coordinates feature launches with documentation

Root Cause: Product launches lack integrated planning ensuring documentation, training, and support resources are ready before features reach customers.

This demonstrates how customer-facing problems often trace back to internal coordination issues. The solution isn’t hiring more support staff but preventing problems that generate unnecessary requests.

7 mistakes that derail root cause analysis

Even simple frameworks like the 5 Whys can fall apart when teams rush the process or apply it incorrectly. These common mistakes prevent teams from reaching real, fixable root causes.

- Accepting surface-level answers: Stopping at the first plausible explanation leads to symptom fixes, not lasting solutions. If the answer sounds like a circumstance rather than a system issue, keep digging.

- Blaming people instead of processes: Root causes framed around individual mistakes (“someone forgot,” “they didn’t follow up”) shut down learning. Effective analysis asks why the system allowed the mistake to happen at all.

- Working without cross-functional input: Analyzing problems in silos misses dependencies between teams. Many operational failures originate at handoffs between departments, not within them.

- Forcing linear logic onto multi-cause problems: Some issues have multiple independent contributors. Treating these as single-cause problems oversimplifies reality and leads to incomplete fixes.

- Skipping root cause verification: Teams often assume they’ve found the root cause without testing it. If fixing the identified issue wouldn’t reliably prevent recurrence, the analysis isn’t finished.

- Using vague problem statements: Broad definitions like “performance issues” or “low satisfaction” lead to unfocused questioning. Strong analysis starts with specific, measurable problem statements.

- Failing to follow through on corrective actions: Insight without execution changes nothing. Without ownership, deadlines, and tracking, even correct root cause analysis fails to deliver results.

Root cause analysis only creates value when it leads to implemented, verified change. Embedding follow-up actions directly into team workflows — rather than treating analysis as a standalone exercise — is what turns insight into prevention.

Transform your 5 Whys with AI and automation

Technology enhances traditional 5 Whys analysis by providing intelligent guidance, pattern recognition, and automated follow-through. This doesn’t replace human judgment but amplifies it.

AI-powered question guidance

Artificial intelligence suggests relevant follow-up questions based on previous answers. This helps teams avoid shallow analysis and explore causal paths they might not have considered.

Natural language processing analyzes answer patterns to identify when responses are too vague, too person-focused, or too surface-level. When these patterns appear, AI prompts teams to dig deeper with specific suggestions. AI Blocks in monday work management can categorize problem types, analyze answer patterns, and suggest investigation paths based on successful past resolutions.

Automated pattern detection

AI identifies recurring themes across multiple analyses, revealing systemic issues that individual sessions might miss. When 3 different teams trace problems back to “inadequate onboarding processes,” pattern recognition flags this as an organizational priority.

The system tracks which root causes appear most frequently, which have the highest business impact, and which remain unresolved despite action plans. This transforms isolated problem-solving into organizational learning.

Smart action item generation

AI suggests specific, actionable solutions based on identified root causes and organizational context. It learns from successful past implementations to improve future recommendations.

When analysis identifies “no formal communication between departments” as a root cause, AI might suggest creating a shared project board with automated notifications. monday work management’s automation capabilities can implement many suggested solutions directly, creating recurring work items, notification rules, approval workflows, or dashboard alerts.

Build systematic problem-solving capabilities

The 5 Whys method transforms how organizations approach problems, moving from reactive firefighting to proactive prevention. Teams that master this technique develop stronger analytical thinking skills and create lasting solutions that prevent recurring issues.

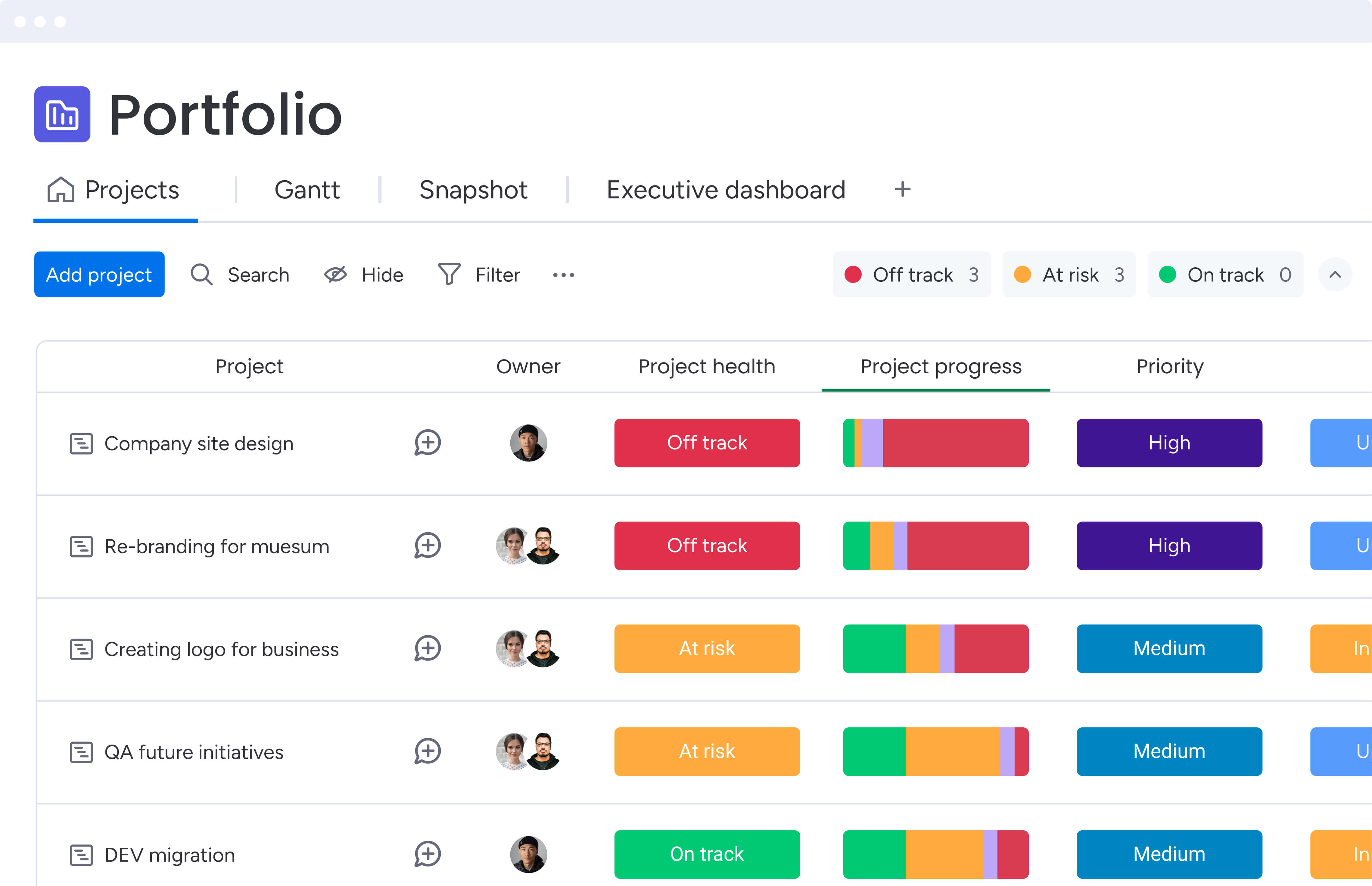

With monday work management, root cause analysis is embedded directly into the workflows teams already use for project management, operations, and collaboration. The platform’s dashboard and reporting capabilities identify recurring root causes across multiple analyses, enabling systemic improvements rather than isolated fixes, giving executives visibility into problem-solving effectiveness across the organization.

Try monday work managementFAQs

What is the difference between 5 whys and fishbone diagram?

The difference between the 5 Whys and a fishbone diagram is their approach. The 5 Whys follows a linear questioning path to identify single root causes, while fishbone diagrams explore multiple potential causes simultaneously across different categories. Fishbone diagrams explore multiple potential causes simultaneously across different categories like people, processes, equipment, and materials.

How many whys should you actually ask?

Regarding how many whys you should actually ask, the number "5" is a guideline rather than a strict rule. You should continue asking "why" until you reach a root cause you can address through process changes, resource allocation, or system improvements.

Can you use the 5 whys for complex problems?

The 5 Whys works best for problems with linear cause-effect relationships. Complex issues with multiple independent contributing factors require supplementary methods like fishbone diagrams or fault tree analysis.

What makes a good 5 whys facilitator?

Effective facilitators ask probing questions that push beyond surface explanations, keep discussions focused on facts and processes rather than blame, ensure all team members contribute, and maintain psychological safety.

How do you handle multiple root causes?

When evidence suggests multiple independent factors contribute to a problem, teams should conduct separate 5 Whys analyses for each major causal path. Prioritize root causes based on business impact and implementation feasibility.

What's the best format for a 5 whys template?

Effective templates include a comprehensive problem description section, cascading visual structure showing the questioning progression, dedicated space for root cause summary, and integrated action planning with ownership and deadlines.